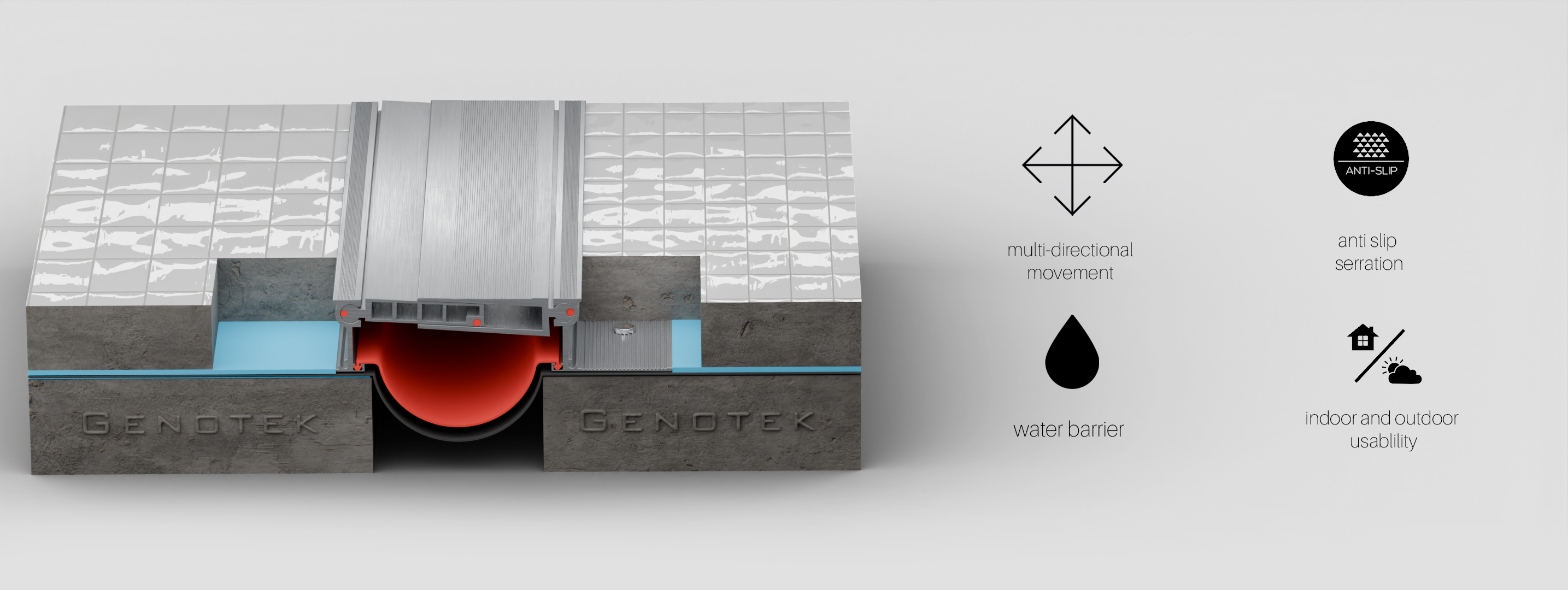

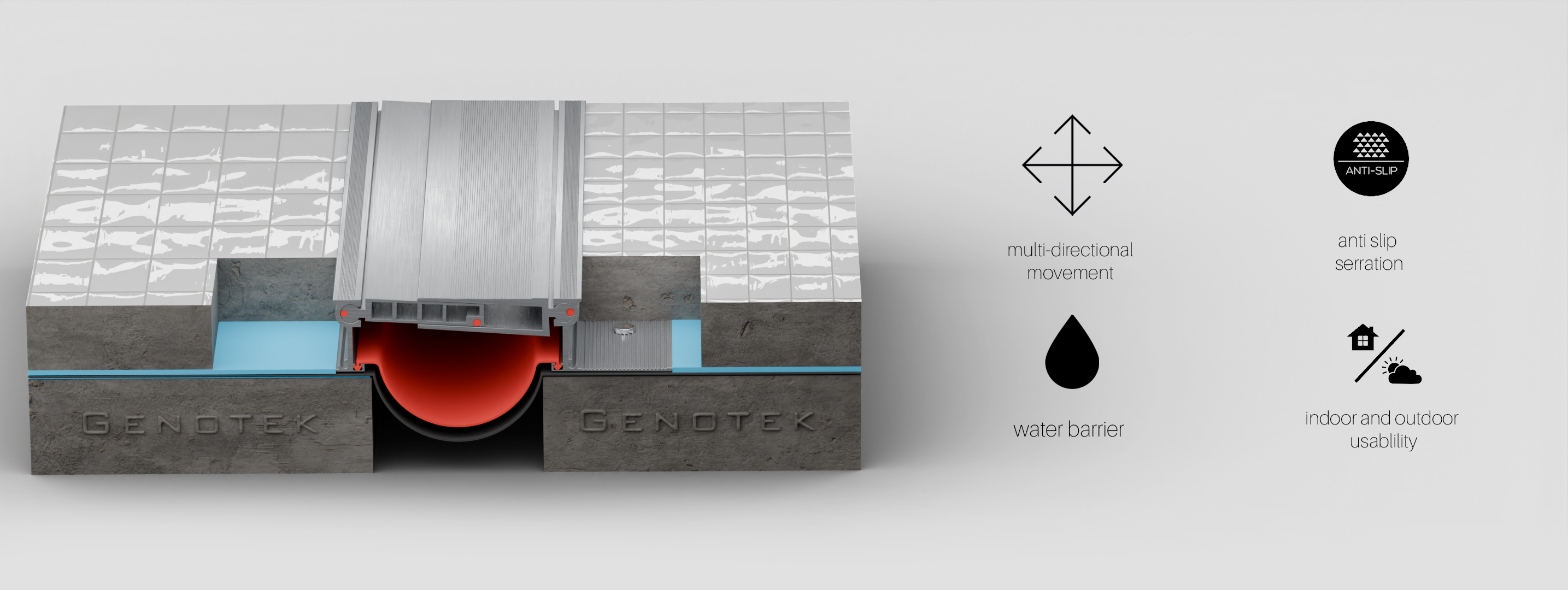

The flexibility expert. witness the SUPERMATE Z 1685's ability to handle slab expansion and contraction caused by thermal, seismic, or settlement activity. this expansion joint cover effortlessly accommodates movement in three directions: horizontal, vertical, and lateral. engineered for durability, the Z 1685 maintains a flawless surface while allowing the slab to move freely during temperature changes or ground shifts. trust the flexibility expert to protect your project from daily stresses and environmental factors, keeping your floors strong and beautiful for years to come.

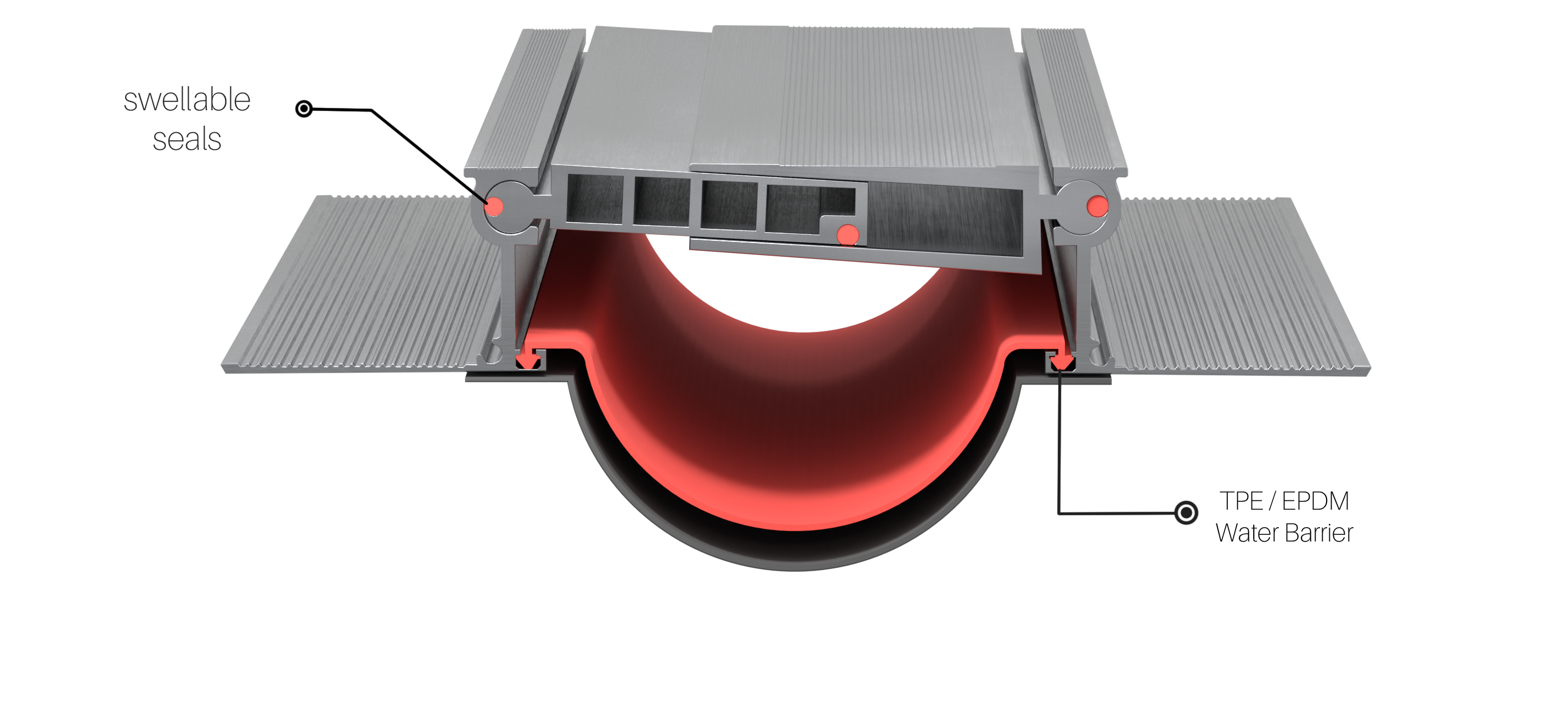

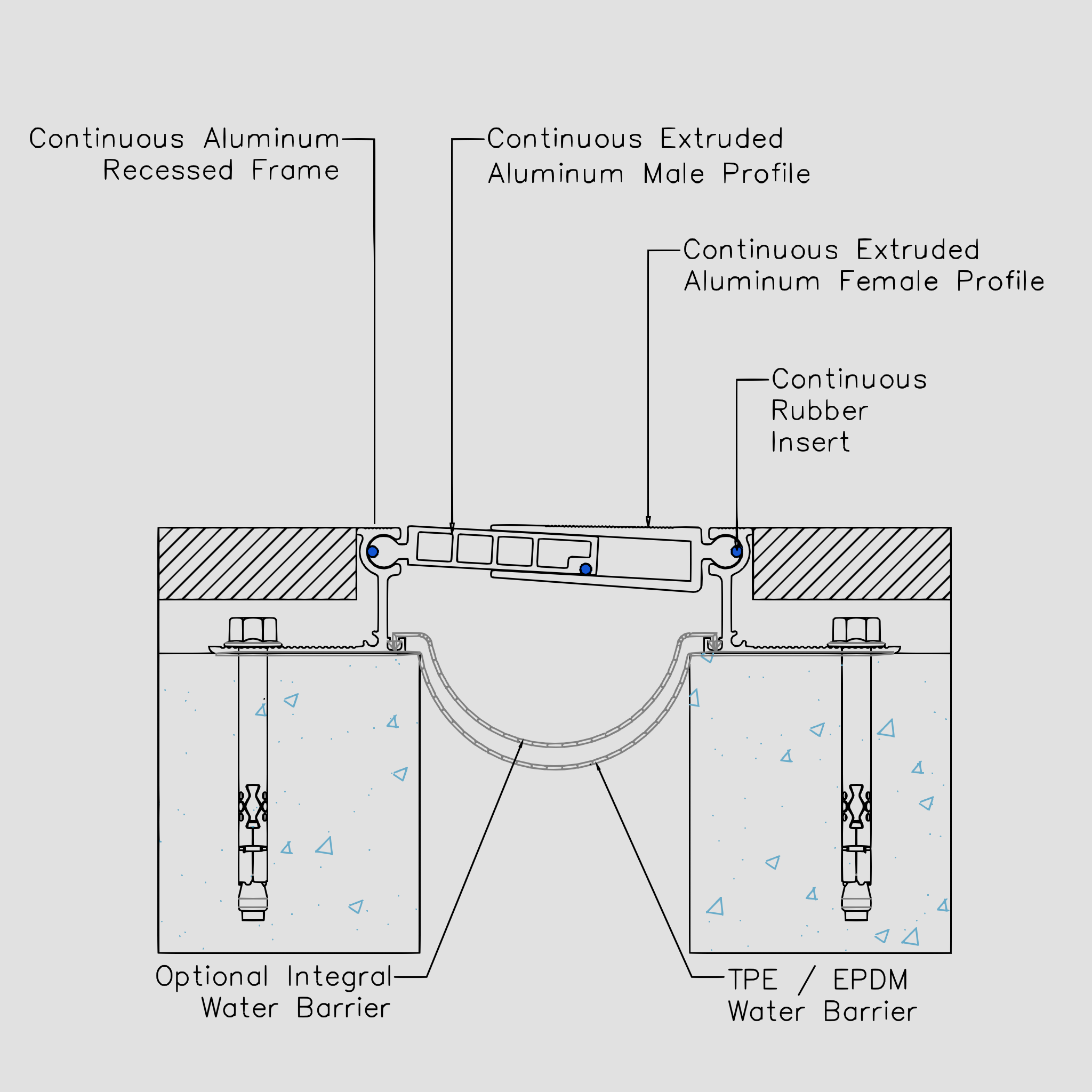

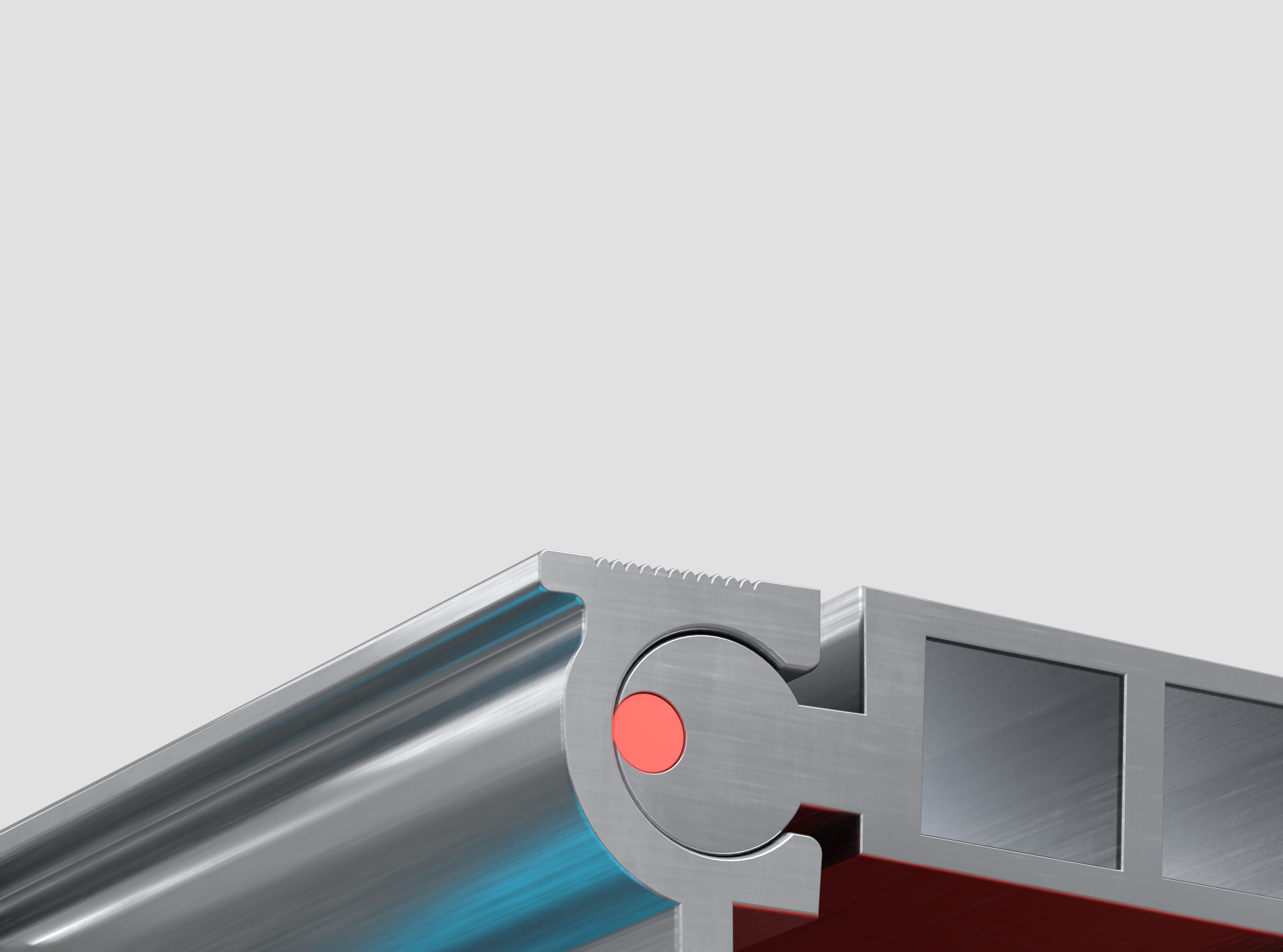

The clip-in water barrier. feel secure with the satisfying snap as the clip-in water barrier locks into place, shielding against leaks. with 300% elongation, it adapts to movement while maintaining integrity. no anchor bolt punctures mean superior protection, even in open-to-sky locations. heat-weldable TPE forms seamless intersections, eliminating weak points. the barrier holds water during rain or washing, then allows evaporation once the source stops. save time with quick installation and enjoy long-lasting protection. experience the simplicity and reliability of the clip-in water barrier.

The SUPERMATE Z 1685 series is designed to accommodate a wide range of load-bearing requirements. Whether your project involves light pedestrian traffic or heavy vehicular loads, these expansion joint covers are engineered to withstand the pressure. The Z 1685 series offers various models tailored to your specific needs, ensuring that your floors remain stable and secure under any load. From shopping malls to parking garages and industrial facilities, trust the load bearer to provide the right level of support for your application.

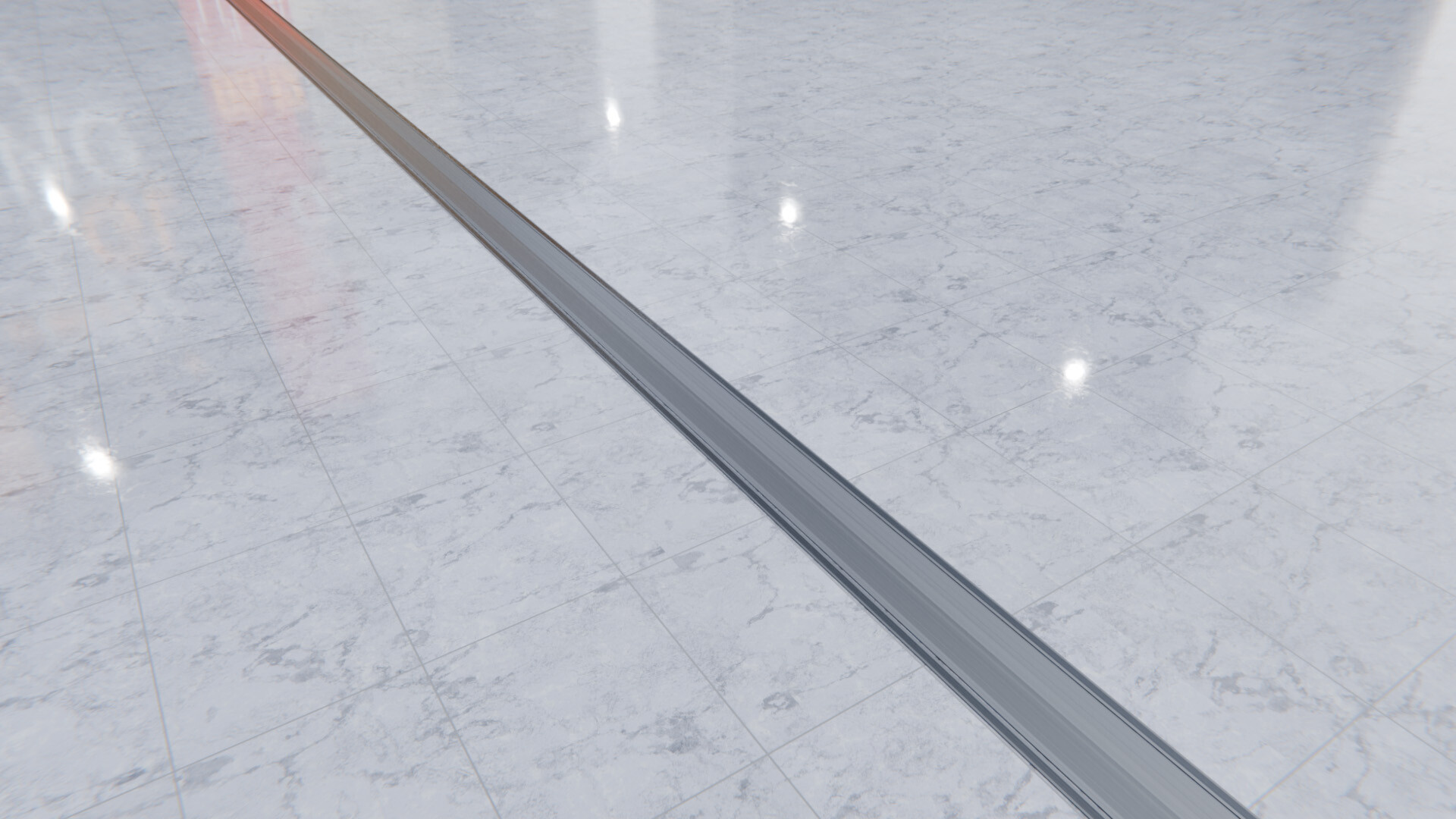

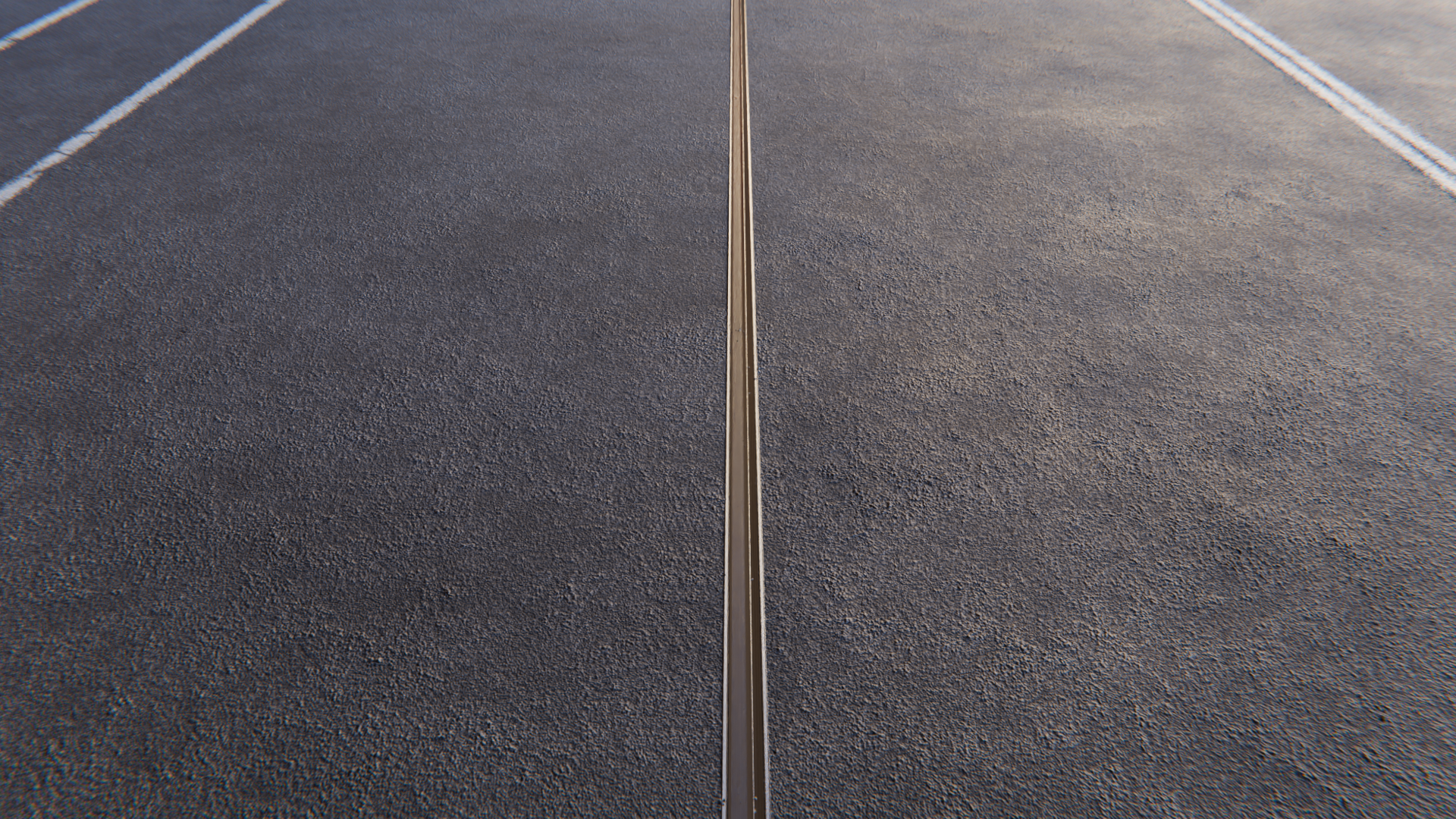

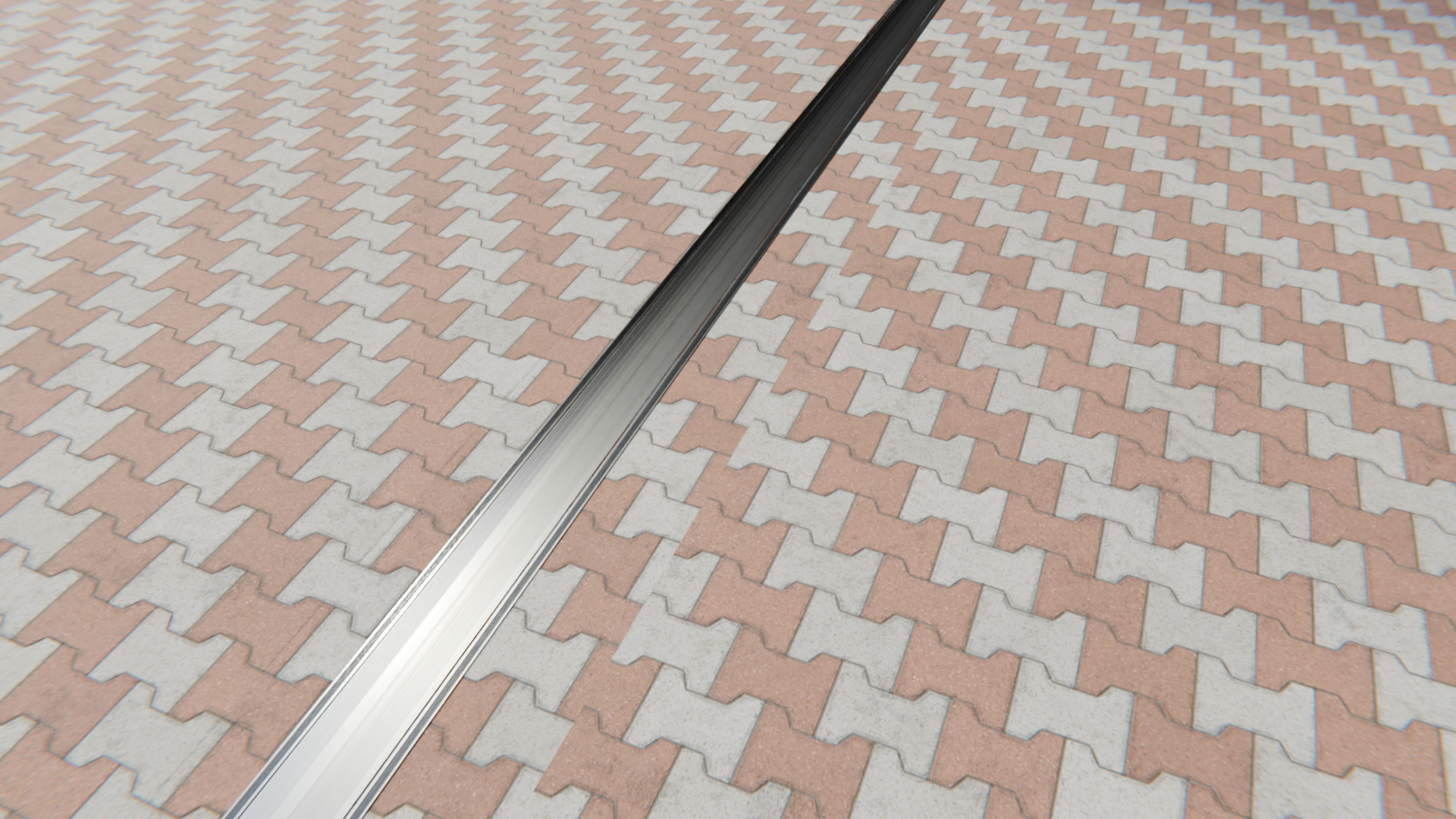

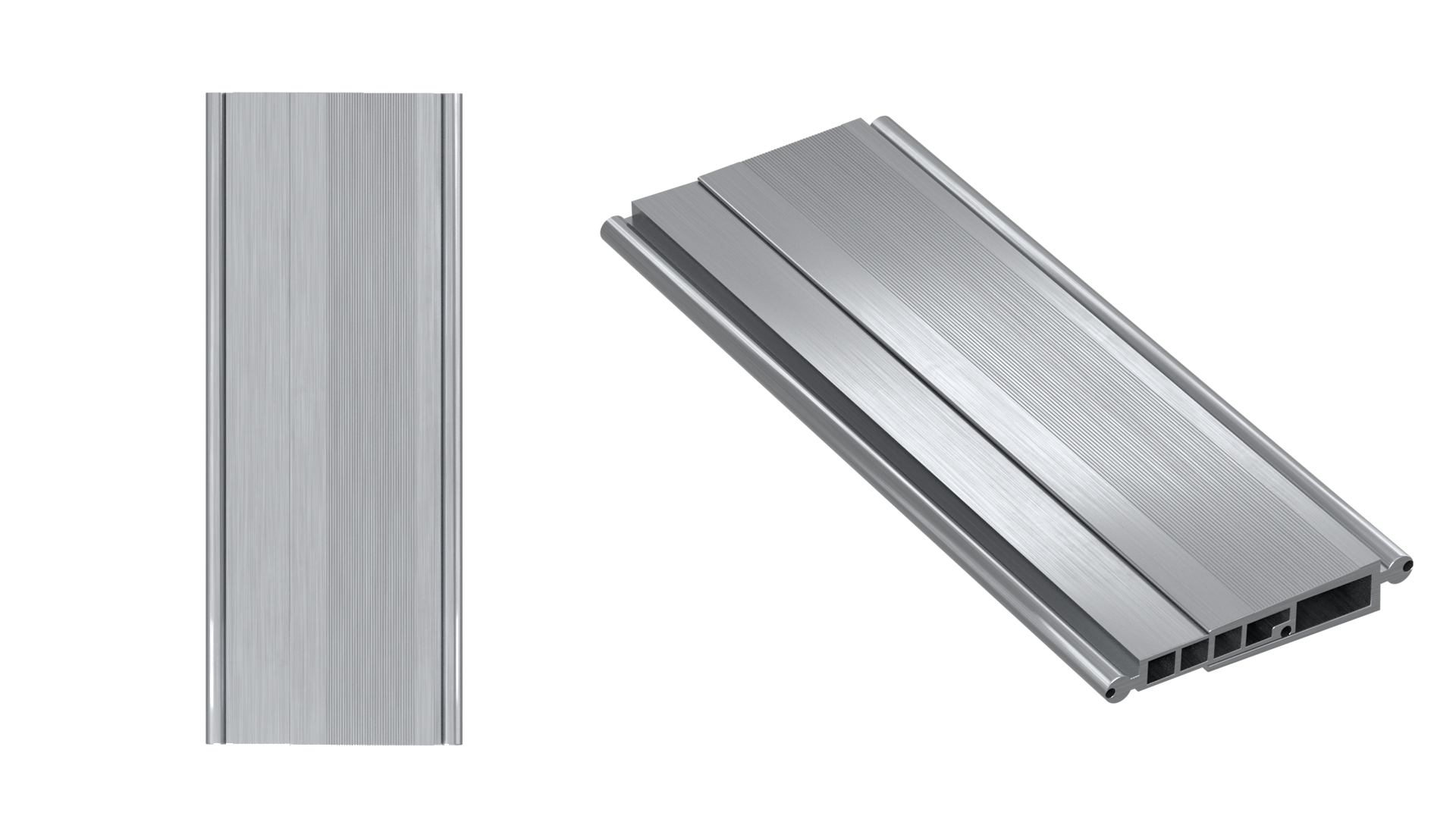

the aesthetic champion. the SUPERMATE Z 1685, crafted entirely from sleek aluminum, effortlessly complements any floor finish. whether you're working with polished concrete, rustic pavers, elegant marble, or modern tiles, this expansion joint cover seamlessly blends in, enhancing the overall aesthetic of your space. trust the Z 1685 to provide not only exceptional functionality but also a touch of sophistication to your project, no matter the design style.

The honeycomb structure in an expansion joint is engineered to optimize load distribution and minimize deflection. Comprising a hexagonal lattice, it efficiently absorbs and redistributes stress, allowing the joint to withstand significant loads without compromising structural integrity. This design enhances flexibility and durability, providing superior performance in handling both thermal expansion and mechanical loads while maintaining minimal deflection. The result is a robust yet adaptable joint that supports maximum load capacity and longevity in various applications.

The cylindrical hinge in an expansion joint enables smooth, multi-directional movement, accommodating axial, lateral, and rotational forces. Its cylindrical design ensures even load distribution and minimal friction, enhancing durability and flexibility. Engineered for high performance, it effectively manages structural stresses while maintaining alignment, making it ideal for handling thermal expansion and seismic activity in various applications.

The anti-slip serrations in the aluminum surface of an expansion joint provide exceptional traction and safety. These precision-engineered grooves create a high-grip texture that prevents slips and skids, even in wet conditions. The serrated design ensures secure footing for pedestrians and vehicles, enhancing the joint's overall safety and functionality. Engineered for durability and performance, these anti-slip serrations offer a reliable, long-lasting solution for maintaining a safe environment in various applications.

Aluminum grade 6063, the premium material used in the expansion joint cover, offers strength, corrosion resistance, and durability. Available in T5 and T6 tempers or customized to meet project needs, this versatile alloy ensures exceptional structural integrity and longevity. Aluminum 6063 withstands high-traffic areas, extreme temperatures, and corrosive conditions, making it an ideal choice for diverse applications, from commercial facilities to infrastructure projects.

TPE (Thermoplastic Elastomer), the advanced material used in the clip-in water membrane, combines the flexibility of rubber with the strength of thermoplastics. This unique blend enables exceptional waterproofing performance and durability, with resistance to weathering, UV radiation, and chemicals. TPE's flexibility allows for easy installation and adaptability, while its heat-welding capability ensures watertight seals. Utilizing TPE, the clip-in water membrane offers a reliable solution for preventing water damage in expansion joint systems across diverse applications.