PROPARK Series

Floor Expansion Joint Cover

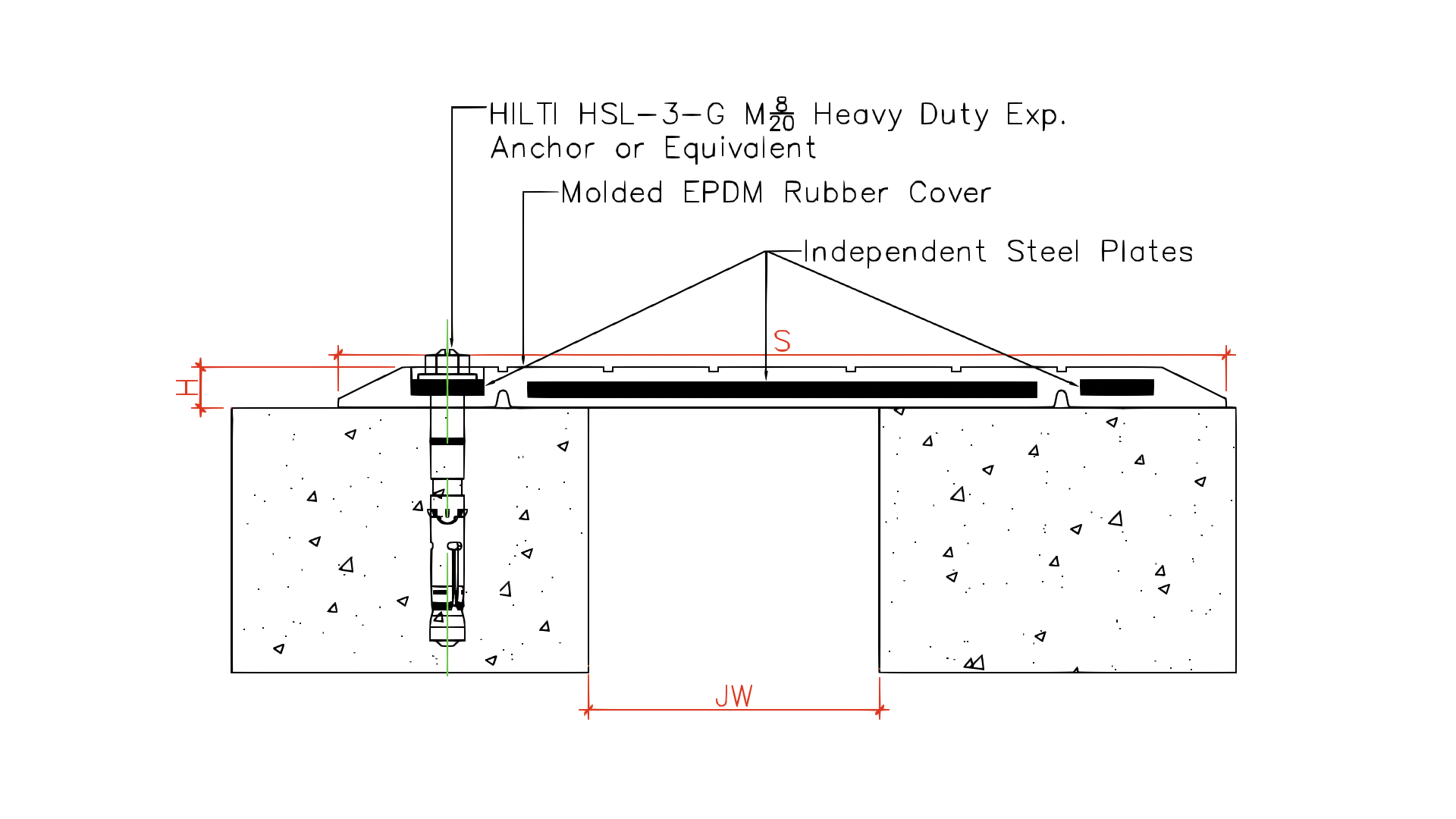

a seismic-ready expansion joint cover engineered for high-traffic floor applications in the most demanding environments. This innovative system is designed to withstand extreme loads while accommodating multi-directional movement, including significant vertical displacement. Ideal for parking structures, stadiums, multi-level car parks, and industrial floors in seismically active areas, the GEN-1000 features a unique three-part design with compression-molded elastomeric rubber encapsulated steel plates. Experience unparalleled protection against thermal expansion, contraction, lateral shifts, and vertical movement with the PROPARK Series GEN-1000.

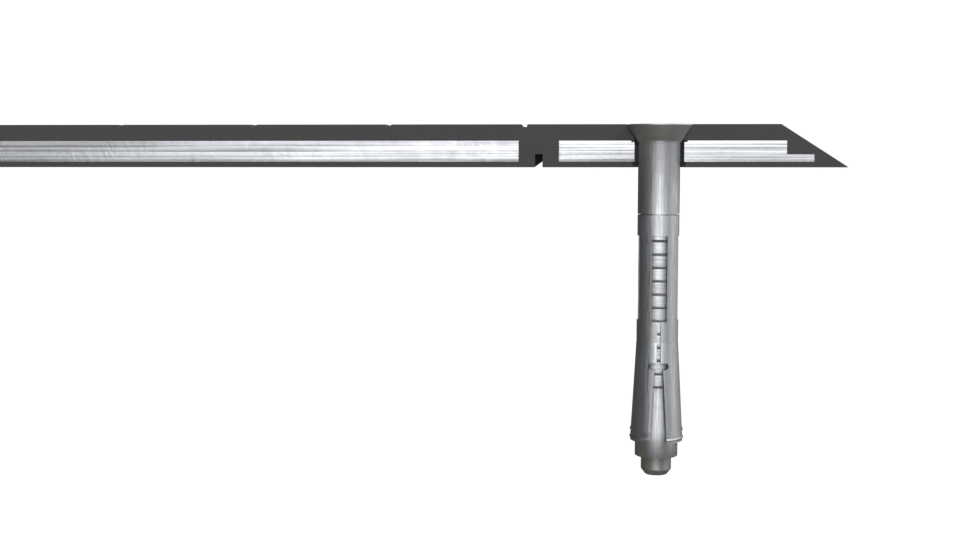

Rigorously tested as per AASHTO and DIN standards, the PROPARK Series GEN-1000 handles challenging heavy-duty loads, including fire trucks and emergency vehicles. Its robust three-part steel core and resilient elastomeric rubber encapsulation ensure exceptional performance and longevity in the most demanding environments.

Designed to accommodate multi-directional movement, including vertical displacement of up to 20-30mm, the GEN-1000 adapts to structural shifts without compromising integrity or functionality. The unique three-part design allows for tilting and flexing, ensuring a secure and stable surface even under extreme seismic conditions.

Water Protection with Conventional Water Barrier only

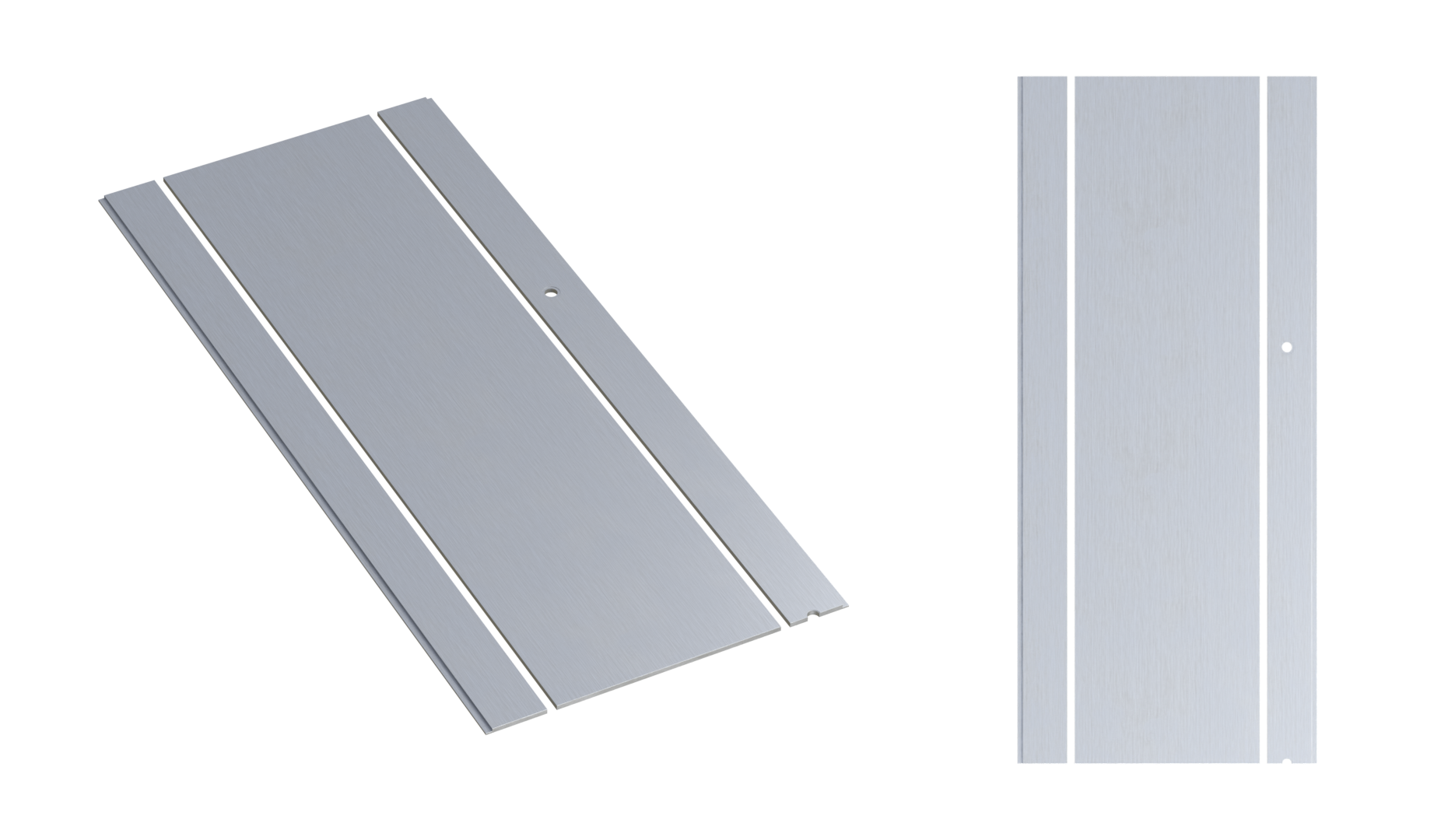

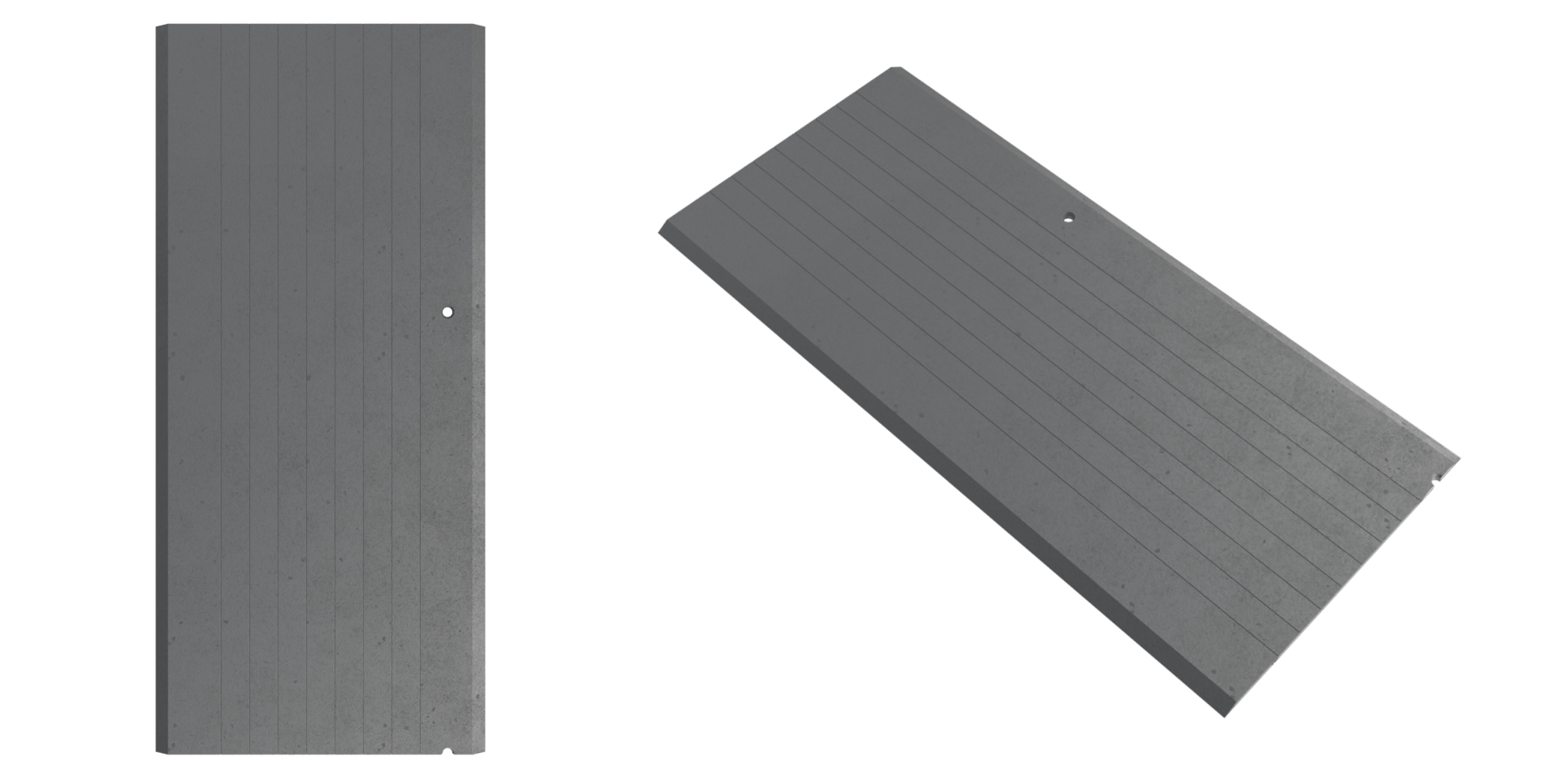

The GEN-1000 features three individual steel plates encapsulated in elastomeric rubber. Parts A and C provide stable support on the slab edges, while the wider center part B bears the main load and allows for vertical tilting, ensuring smooth transitions during seismic events.

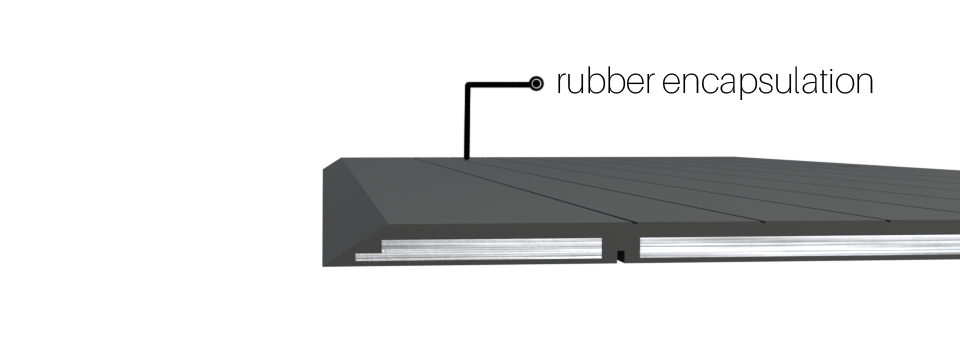

Each steel plate is fully encapsulated by a thick layer of elastomeric rubber using a compression molding process. This design provides superior load-bearing strength, prevents warping or deflection, and offers excellent resistance to weathering, UV radiation, and chemicals, ensuring long-lasting durability in both indoor and outdoor applications.

Unlike conventional metal plates, the PROPARK Series eliminates the risk of galvanic corrosion between the anchor bolt and the plate. The elastomeric rubber encapsulation prevents direct contact between dissimilar metals, ensuring a secure and stable installation that maintains its integrity over time.

The elastomeric rubber construction effectively absorbs sound and vibrations, significantly reducing noise levels when vehicles pass over the expansion joint cover. This feature is particularly beneficial in parking garages, stadiums, and other high-traffic areas where noise reduction is crucial for user comfort and safety.

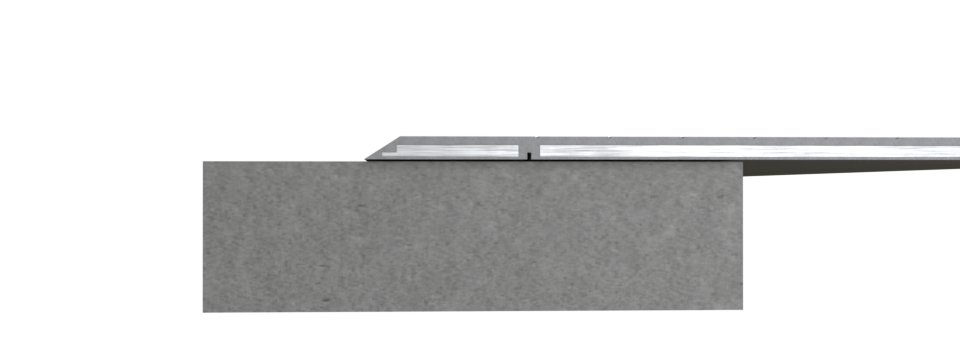

Designed for easy surface mounting directly on the slab, the GEN-1000 is an ideal solution when a recess is not possible or practical. The system's versatile design allows for quick and efficient installation, minimizing downtime and labor costs while providing a reliable and durable expansion joint solution for seismically active areas.

The PROPARK Series GEN-1000 utilizes high-quality elastomeric rubber, specifically formulated for its exceptional durability, flexibility, and resistance to environmental factors. The rubber is compression-molded to fully encapsulate the steel plates, creating a monolithic structure that provides superior protection and performance in high-traffic applications while allowing for seismic movement.

At the core of the GEN-1000 lie three robust steel plates, available in galvanized steel ST37 as standard, stainless steel 304, or stainless steel 316 options. These high-strength steel plates provide the necessary structural integrity to withstand heavy-duty loads and traffic, while their unique configuration allows for vertical movement and settlement. The elastomeric rubber encapsulation ensures long-lasting protection against corrosion and wear, even in seismically active environments.