Construction Materials of the Future

Materials and Techniques Set to Challenge Conventional Building Materials are all phrases that are becoming increasingly common in today's world, but what does it mean for our industry? What does it mean for you? And how can we make sure construction doesn't get disrupted? This article will take a deep dive into these questions.

Construction Materials of the Future

Construction is one of the main industries in society and there are a number of inventions that could change how we build. Construction in the 21st century will be revolutionized by new innovations in material science. One such innovation is graphene, a miracle material made from pure carbon which can be seen as a replacement for steel or aluminum. Graphene has been hailed as “the end-all solution to all our problems” because it is stronger than steel, lighter than aluminum, more flexible than rubber, and highly conductive despite being an excellent insulator. In addition to this strength and flexibility, it also has astonishing characteristics when exposed to light; graphene becomes transparent with interesting optical properties like photoluminescence.

Other materials may prove disruptive to construction as well. Concrete is an excellent building material, but with the recent developments of self-healing concrete, it could be set to become even stronger if cracks form. Although not technically a material innovation, with the increasing affordability of 3D printing technology; industry professionals are starting to anticipate how this advance in manufacture can disrupt Construction with their speedy and inexpensive production methods. Construction is rapidly changing, and although disruption may be difficult for some Construction companies to cope with - these new innovations will bring opportunities for businesses who are willing to embrace change.

Some of the new materials we will take a look at today are:

Graphene

Graphene

Construction companies are responsible for building everything from bridges to buildings, and they employ millions of people around the globe. Construction also has a significant impact on the environment; it's estimated that construction activity accounts for up to 5% of global greenhouse gas emissions (GHGs). New materials like graphene could disrupt this industry, but what is graphene?

Graphene is an allotrope of carbon with many unique properties. It's only one atom thick, making it very strong and flexible. Graphene can be used as a conductor or semiconductor depending on its preparation method which means it has potential applications in electronics and photonics as well as construction.

Graphene could provide a more environmentally friendly future for construction. The widespread use of concrete throughout the industry is having a significant negative environmental impact, but graphene has been shown to improve the properties of cement-based materials. There are also several ways that graphene could be used to make buildings stronger and safer, such as graphene aerogels which have extremely high strength even at low density. Graphene aerogels could also be used as fire retardants and thermal insulators, opening up possibilities for insulated glazing and green roofs. These types of building components would help reduce energy consumption and improve comfort by regulating temperature and airflow within homes and workplaces respectively. Furthermore, it's likely that graphene will play an important role in the future of electric cars, which could improve our transportation infrastructure.

What do you think about the potential impact graphene could have on Construction Industry, let us know by leaving a comment below?

Self Healing Concrete

Self-healing concrete is a composite material that is able to heal itself over time. This material is composed of different types of polymers and minerals. It's combined in such a way that the cracks get sealed by the reactants and start healing themselves. Polymers break down into smaller molecules that stimulate the formation of new minerals and other compounds. The polymers chain together and form a patch, which fills up the crack and starts creeping out and up along the vertical surface, filling the hole and creating a durable seal.

This article also covers cementitious composites, which are basically materials enhanced with special compositions to improve their mechanical properties. They typically comprise hydrated or unpolymerized cement or cement powders plus natural and/or manufactured fibers and fillers such as silica or clay.

Self-healing concrete is a type of material that has been used in buildings and structures such as highways. Since the number of aging high-rise buildings with self-healing technology will increase over time, we can begin to see how this technology could be applied to other areas such as tissue engineering. Tissue engineering is basically producing new tissues and organs using cells and scaffolds onto which cells can grow and develop to form viable biological tissues or whole organs. This includes efforts by pharmaceutical companies, academia, agencies, physicians' groups, biotech startups, and technology companies.

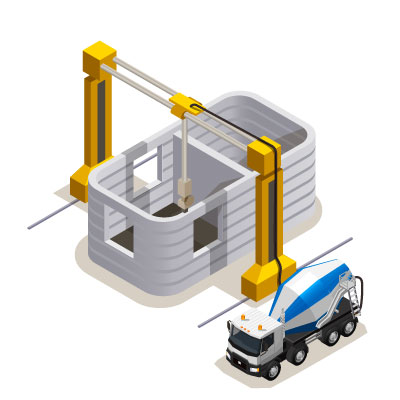

3D Printing in Construction

3D Printing in Construction

Construction companies may also need to consider 3D printing technology as Construction evolves with these new innovations. Construction work may get easier and more efficient if Construction companies begin printing their own parts on site. Construction materials of the future will be very different from those used now as Construction companies transition from mostly manual labor to more digitalized technology.

The construction industry is about to be disrupted by 3D Printing Construction. Construction companies are already using a type of 3D printing technology known as BIM, or Building Information Modeling, which is used for the design and visualization process. Construction companies can now use this same technology to print buildings that look like they came from Star Trek! The potential benefits of 3D printed buildings are endless: Imagine being able to create homes with all the appliances and features you want in any color you choose - without needing expensive tools or skills. All it takes is a computer program! With this new innovation in construction, we will soon have houses built on-site instead of shipping them from factories overseas, making our communities more sustainable and efficient than ever before.

3D printing is coming into homes very soon. 3D printers are becoming smaller and cheaper every year, which means they may soon be affordable for ordinary people to own at home. This will make it easy for people to print any item they need, from furniture, toys or even food! Construction companies are already using a type of 3D printing technology known as BIM, or Building Information Modeling, which is used for the design and visualization process. Construction companies can now use this same technology to print buildings that look like they came from Star Trek! The potential benefits of 3D printed buildings are endless: Imagine being able to create homes with all the appliances and features you want in any color you choose - without needing expensive tools or skills. All it takes is a computer program! With this new innovation in construction, we will soon have houses built on-site instead of shipping them from factories overseas, making our communities more sustainable and efficient than ever before.

One of the most notable examples of an architectural 3D printed building is in Dubai. Construction began on this building in 2013, and it was completed in 2016. The project was initiated by a company called Winsun with the goal of utilizing innovative materials to build sustainable homes at a low cost.

The first iteration of this project involved a small-scale model that demonstrated how 3D printing could reduce construction time from months to days, as well as drastically reduce labor costs. Construction began with a foundation that was made up of a concrete mixture before the printers were put into action for the "skeletal" structure that would eventually be built out with insulation and other materials to make it inhabitable. Construction site crews were able to print the building in about 10 hours, and the printers themselves were capable of working around the clock. This allowed construction to progress at a rapid pace and stay within budget since it did not require highly skilled laborers to complete the project after its initial setup.

While this could be considered an architectural feat, this was merely an experiment that demonstrated how cost-effective 3D printed buildings can be for Dubai's government. Construction on these homes will continue through 2017 with larger scale projects for residents who are currently displaced due to the recent floods experienced throughout parts of Asia .

In addition, Construction may also see a change in the way Infrastructure projects are executed. This could be because of the introduction of new innovative Construction materials and Construction machinery e.g. driverless skid-steer vehicles that can perform multiple tasks simultaneously or be able to lay 2 times as much floor tile per day thanks to robotics and self-driving vehicles on Construction sites.

Construction companies will need to invest in these machines if they want to keep up with the competition and remain relevant, otherwise, Construction projects will take longer than necessary because Construction companies would have been so focused on manually completing tasks rather than managing multiple tasks at once thanks to Construction robotics.

Construction is changing and Construction companies need to be ready for the future of Construction or risk becoming obsolete in this industry.

Conclusion: Revolutionary construction materials will disrupt the way.

How should Construction Stakeholders prepare for the future?

Construction companies should prepare for these changes Construction in the 21st Century Construction material construction materials suppliers Construction has already seen some disruptive change thanks to robotics, digitalization, 3D printing, and self-healing concrete. Construction companies are ready for further disruption as materials science is scheduled to make even more shocking changes. Construction materials suppliers will face significant challenges over the next decade as material science makes its mark on Construction. The biggest challenge that Construction Materials companies will have to cope with is being able to adapt their range of products rapidly enough to accommodate newly developed alternatives or newly available versions of existing products. Graphene may be one alternative to steel, but Construction companies need to be ready for new materials and products like Graphene to become available on the market, and quickly. Construction is a fast-moving industry and Construction companies that don’t adopt new technologies will fall behind their competitors.

Topics from this blog: Blog For Architect For Contractor

Back