About Genotek

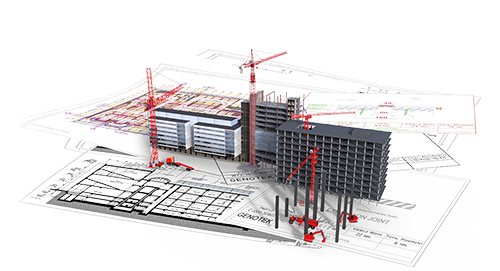

Genotek specializes in developing architectural and engineering solutions for construction projects across a multitude of fields including hotels, airports, shopping malls, industrial plants, parking buildings, stations, exhibition halls, hospitals, and many more across the globe.

The products we are specifically going to talk about here are Expansion Joint Covers.

Advantages of choosing Genotek

Specification Assistance

Genotek provides Specification Assistance to Distributors and Affiliates who would like to approach Architects, we ensure our specification writing provides you with an edge when it comes time for procurement by including details that competitors find hard to comply with.

Fast Track Delivery

Streamlined Supply Chain enables us to offer our clients Supply of our products in as little as 3 Days from date of order. We offer delivery via Air, Sea and Road transport to ensure your products get delivered when you need them.

Superior Warranty

Our Industry Leading Warranty offers our clients peace of mind and ensures we take their reputation seriously.

Installation Support

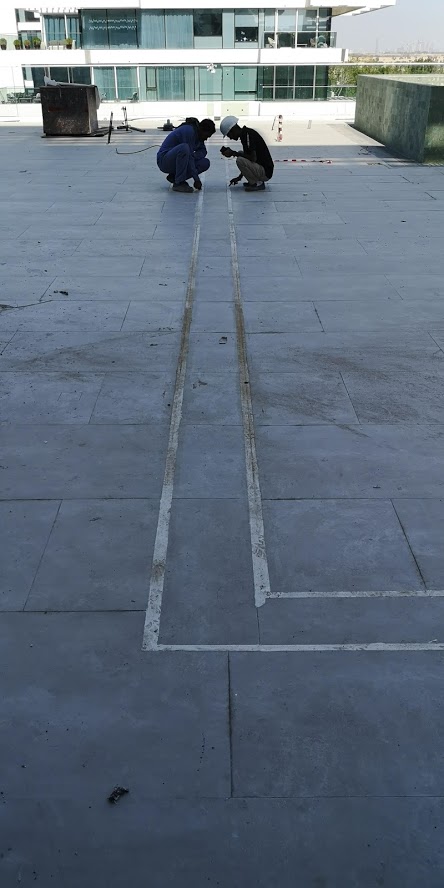

Genotek provides Technical Installation and Supervision services to ensure our products are installed correctly. Approved Installers are also available internationally.

Best Price Guarantee

Our Distributors/Clients save an average of 30% on Material Costs by buying from the factory direct. We practice Agile and Direct-to-Customer supply chain strategies which avoid multiple-tier distribution markups.

Genotek has presence across the globe with a number of technical support centres and state of the art manufacturing facilities.

Genotek has manufacturing facilities in Turkey, United Arab Emirates and India which follow best practices in accordance with international Standards.

Genotek has warehousing facilities across Asia and Europe which allows us to have rapid delivery times to service a large region.

We service our clients and distributors through a network of Sales and Technical Support Centers across the globe.

Our Products

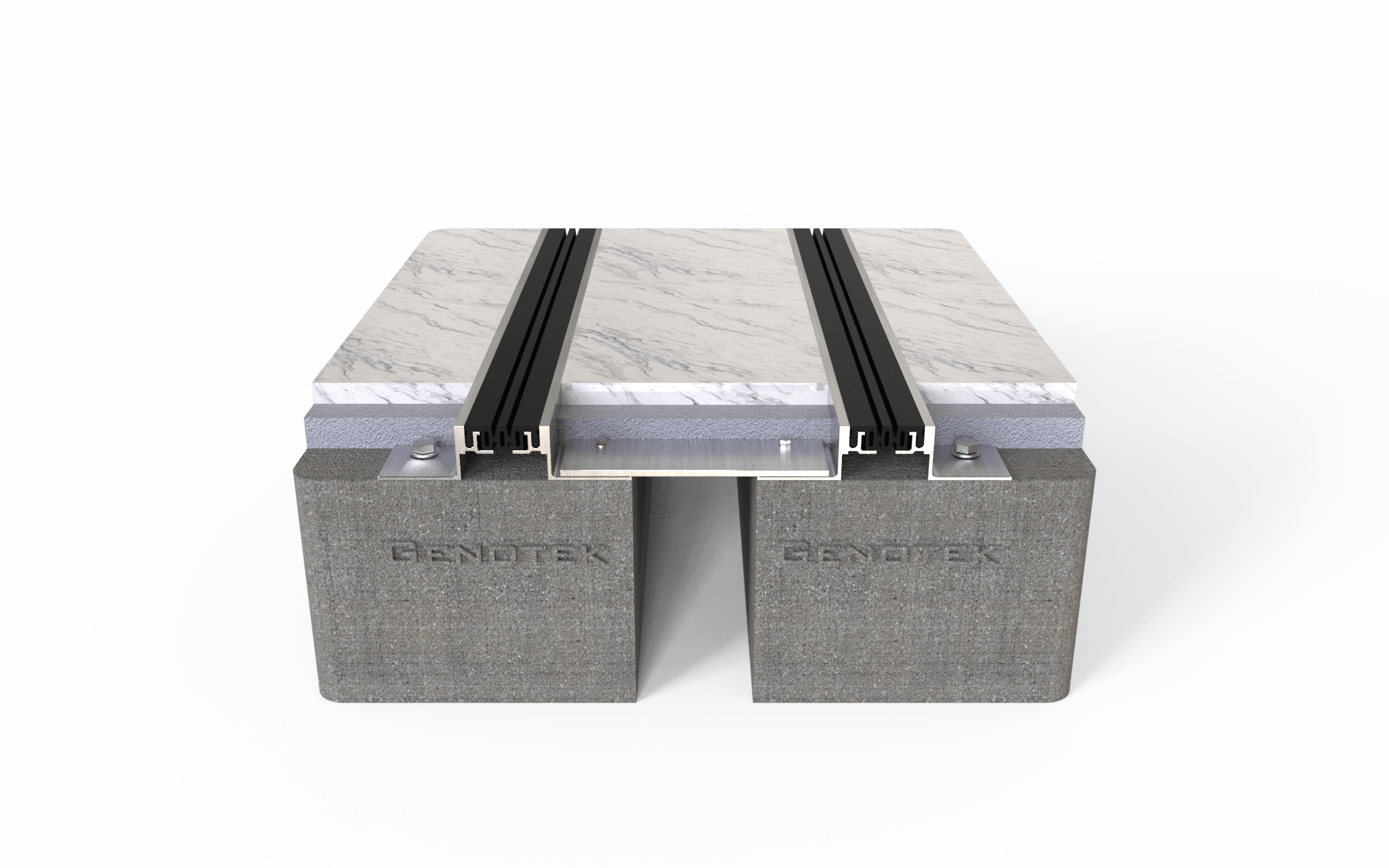

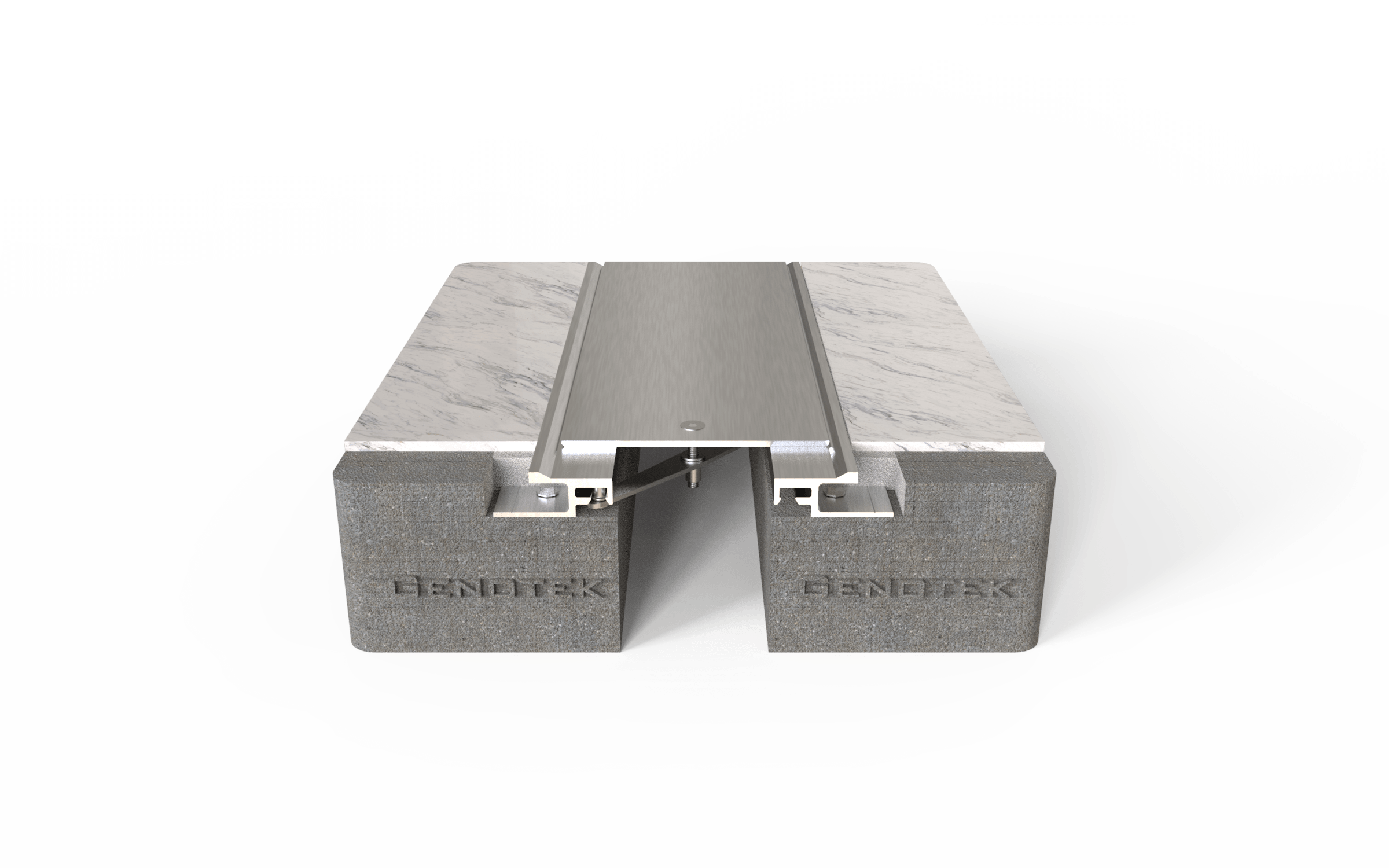

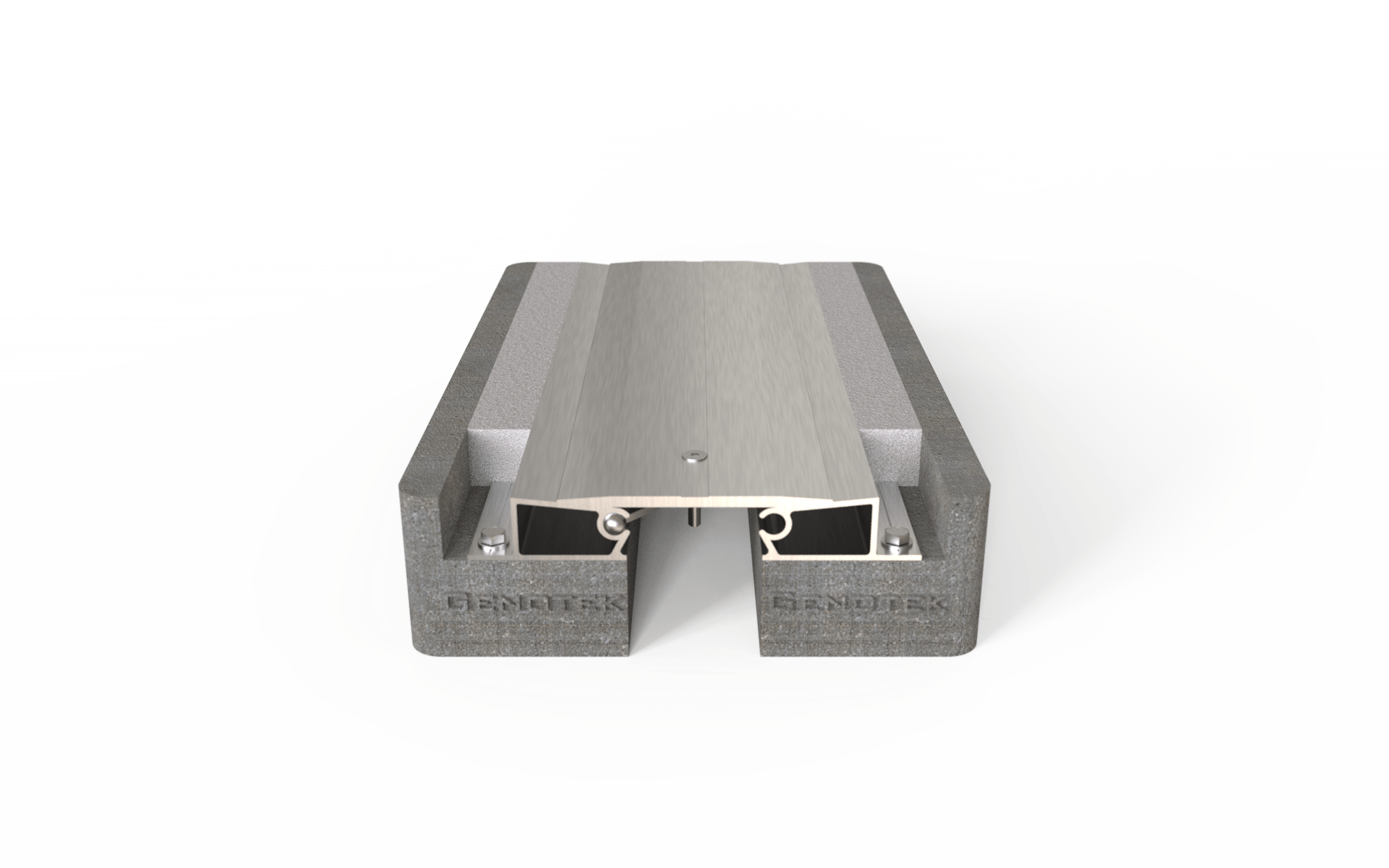

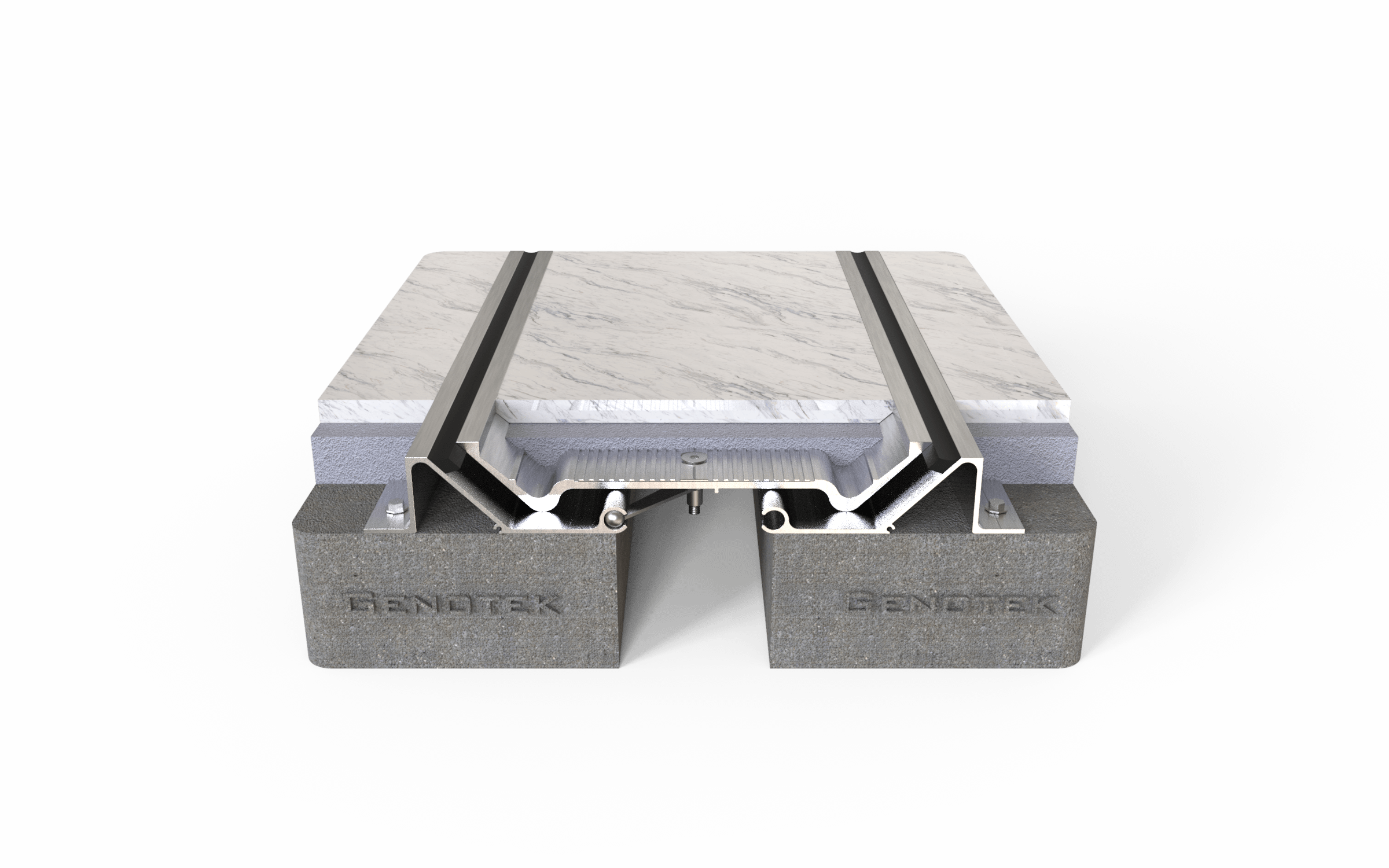

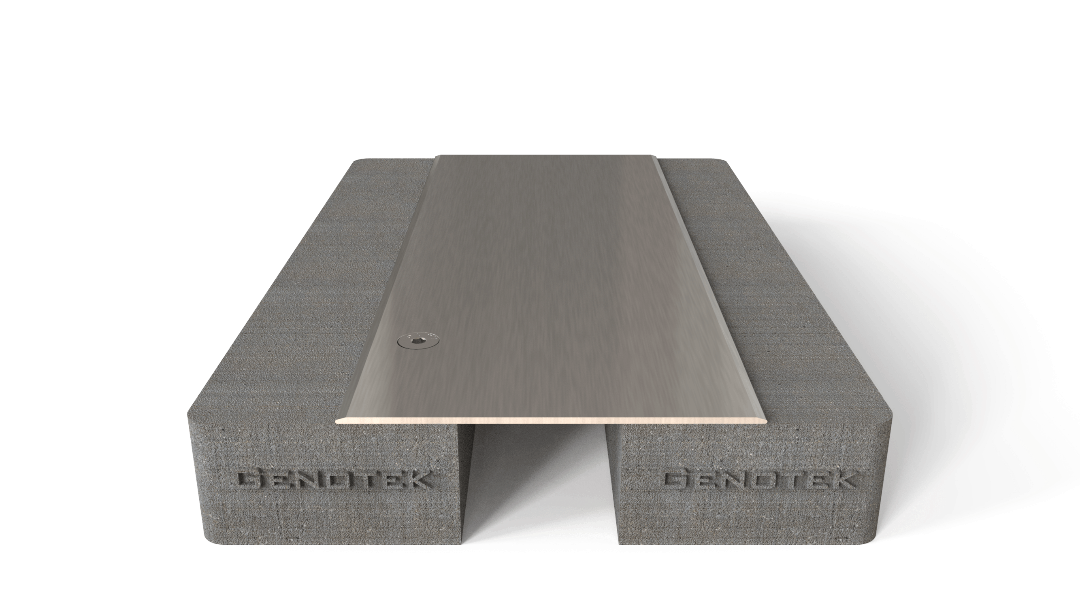

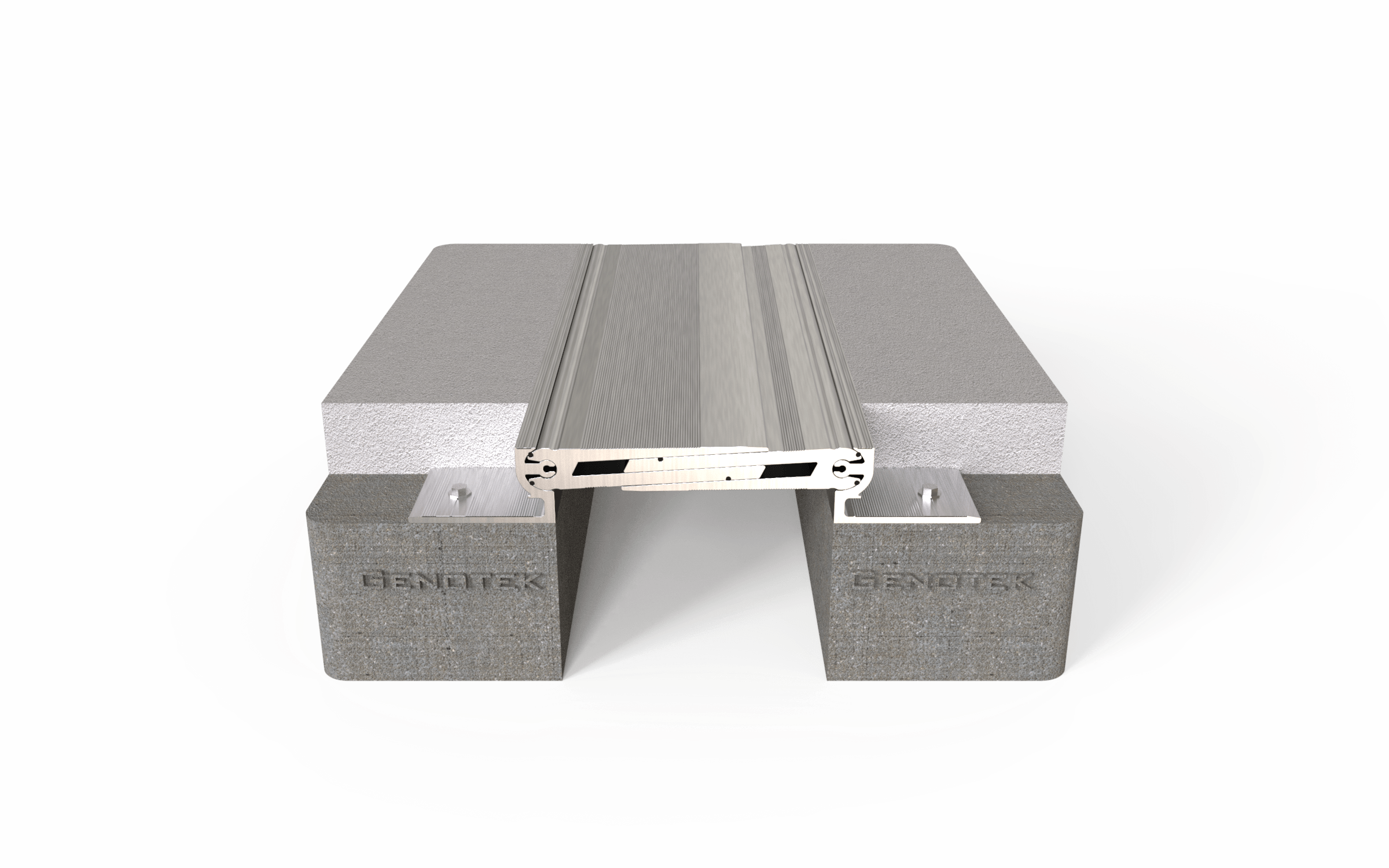

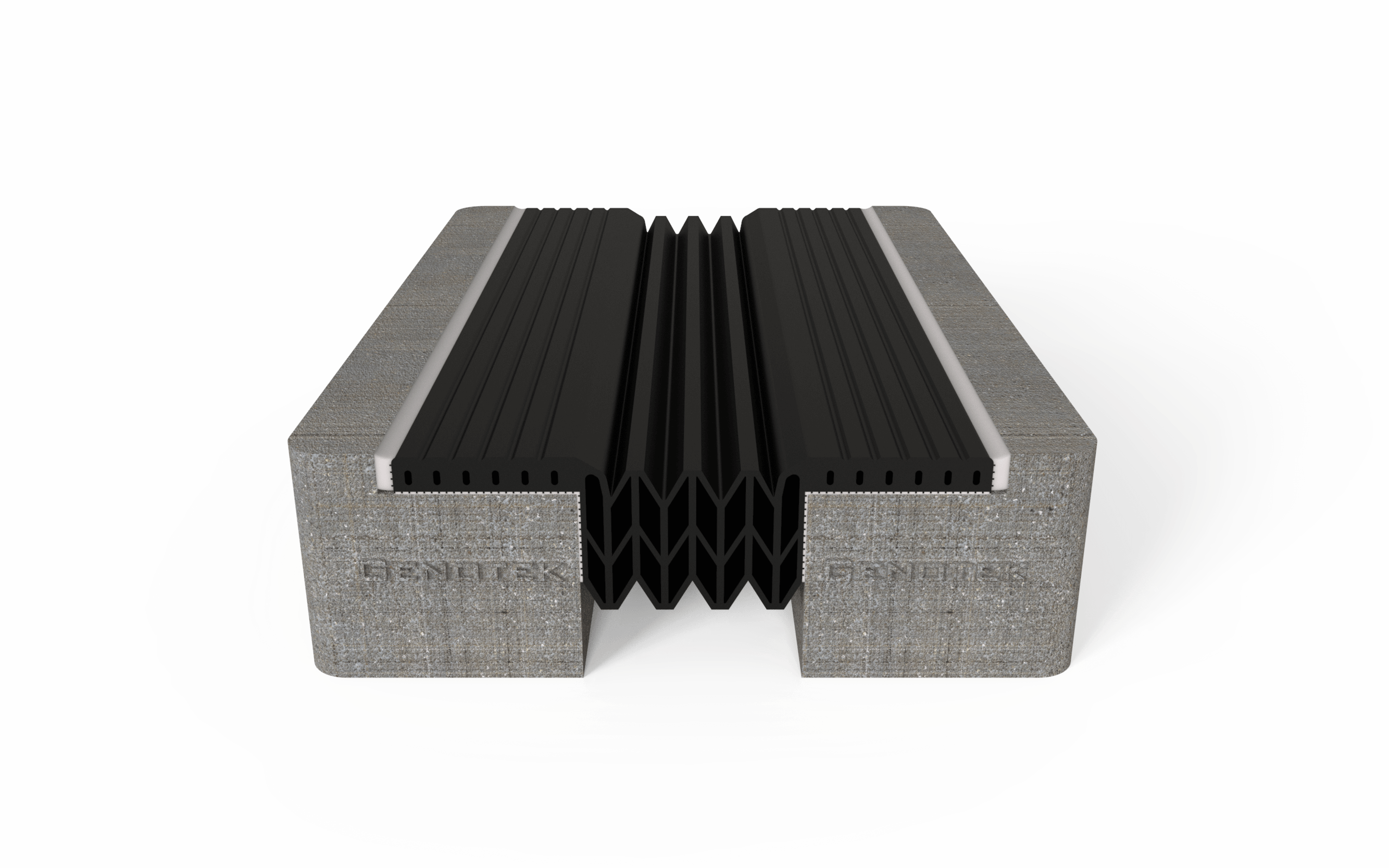

EXPANSION JOINT COVERS

At GENOTEK we have a comprehensive range of Standard and Customizable Expansion Joint Covers to suit individual project needs.

TEMPORARY FLOOR PROTECTION

.png)

GENOTEK Building Protection Systems increase the longevity of the building structure and finishes.

MOVEMENT CONTROL JOINTS

We provide a customized range of Movement Control Joints for Stone and Tile finishes available in a range of standard 10 colours.

ENTRANCE MATTING SYSTEMS

.png)

GENOTEK has been taking care of the floors of its clients since 2005. For us, maintaining clean and shiny floorings is a matter of honor. We offer a full range of professional doormats effectively protecting floor surfaces from unwanted dirt. Cleaning systems and smart technologies that we employ are capable of retaining dirt. As a result, they allow to avoid high costs of cleaning, extend the floor lifespan and guarantee high aesthetics of the interior.

STAIR NOSING AND TILE TRIMS

.png)

You can choose from a wide variety of Stair-nosing profiles and tile trim profiles that best suit your preference.

Section 2 - Technical Training of Expansion Joint Cover Systems

What is an Expansion Joint?

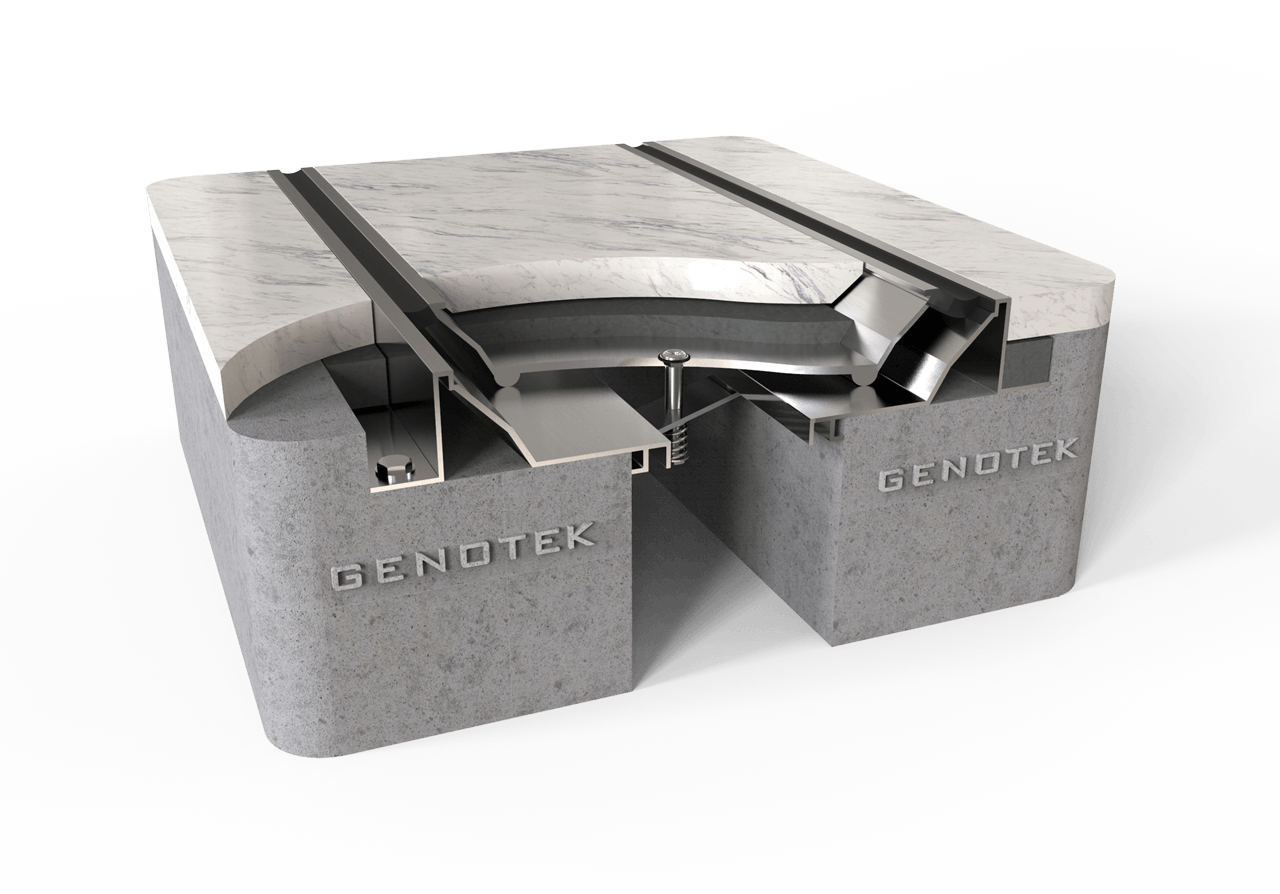

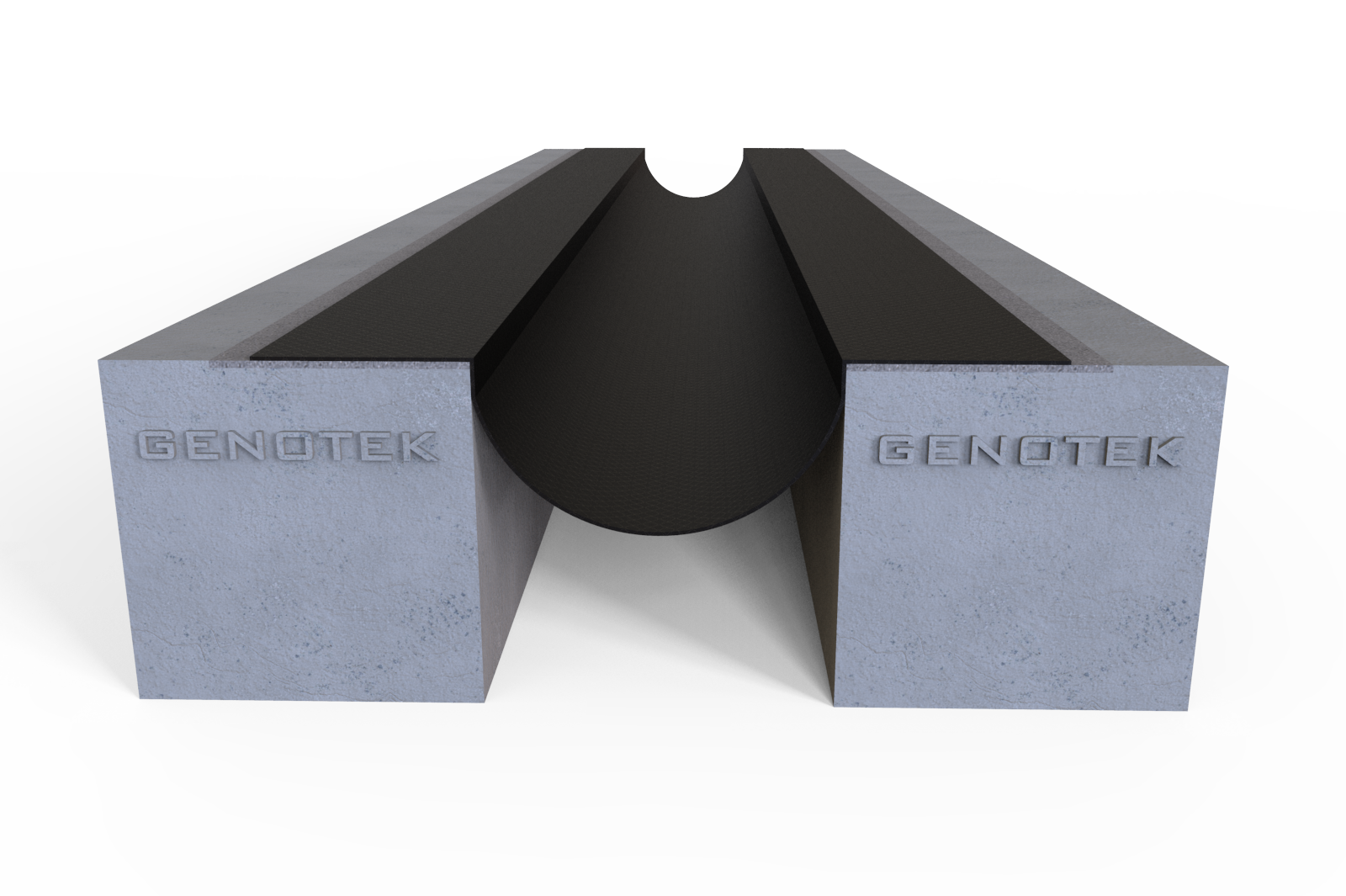

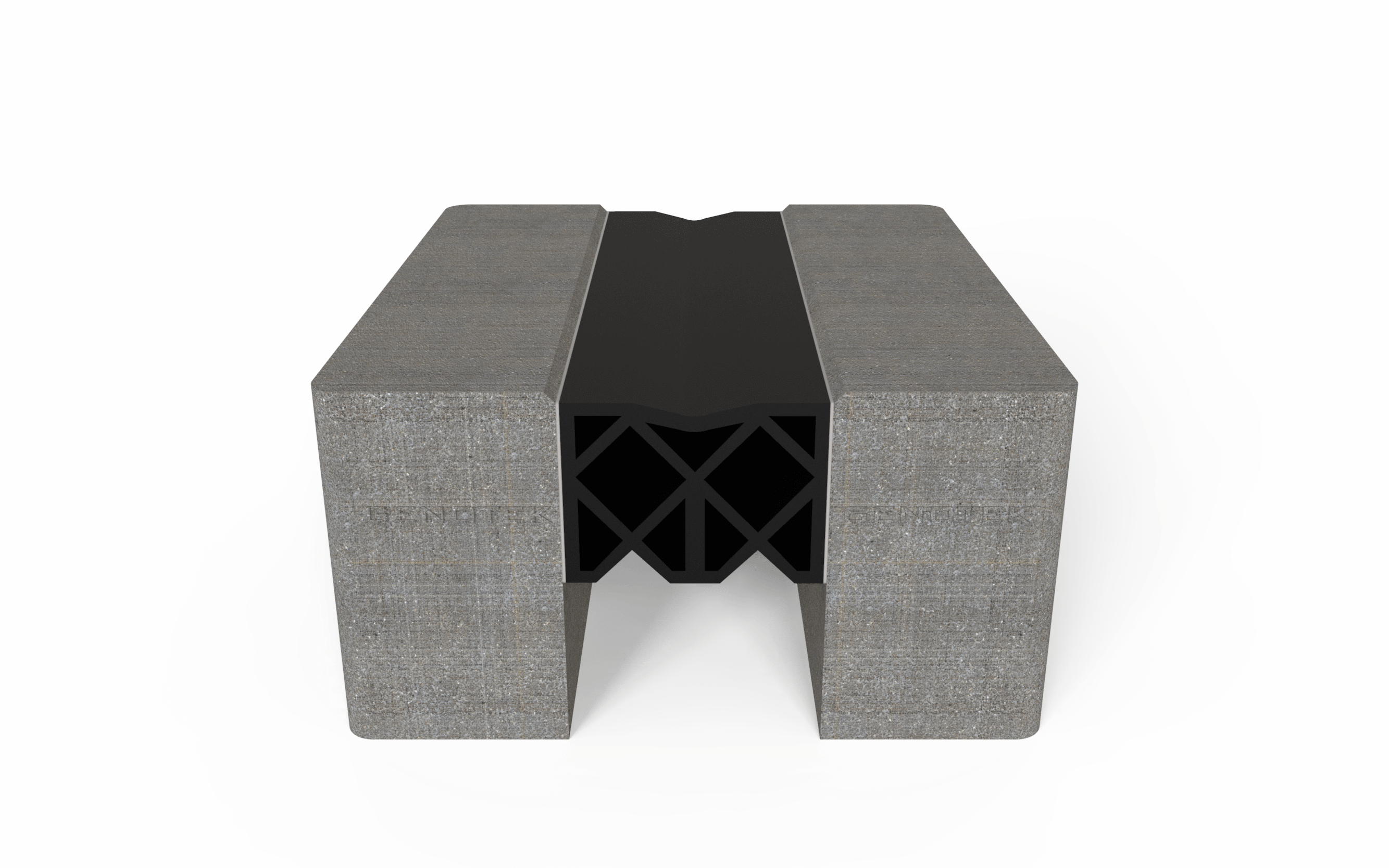

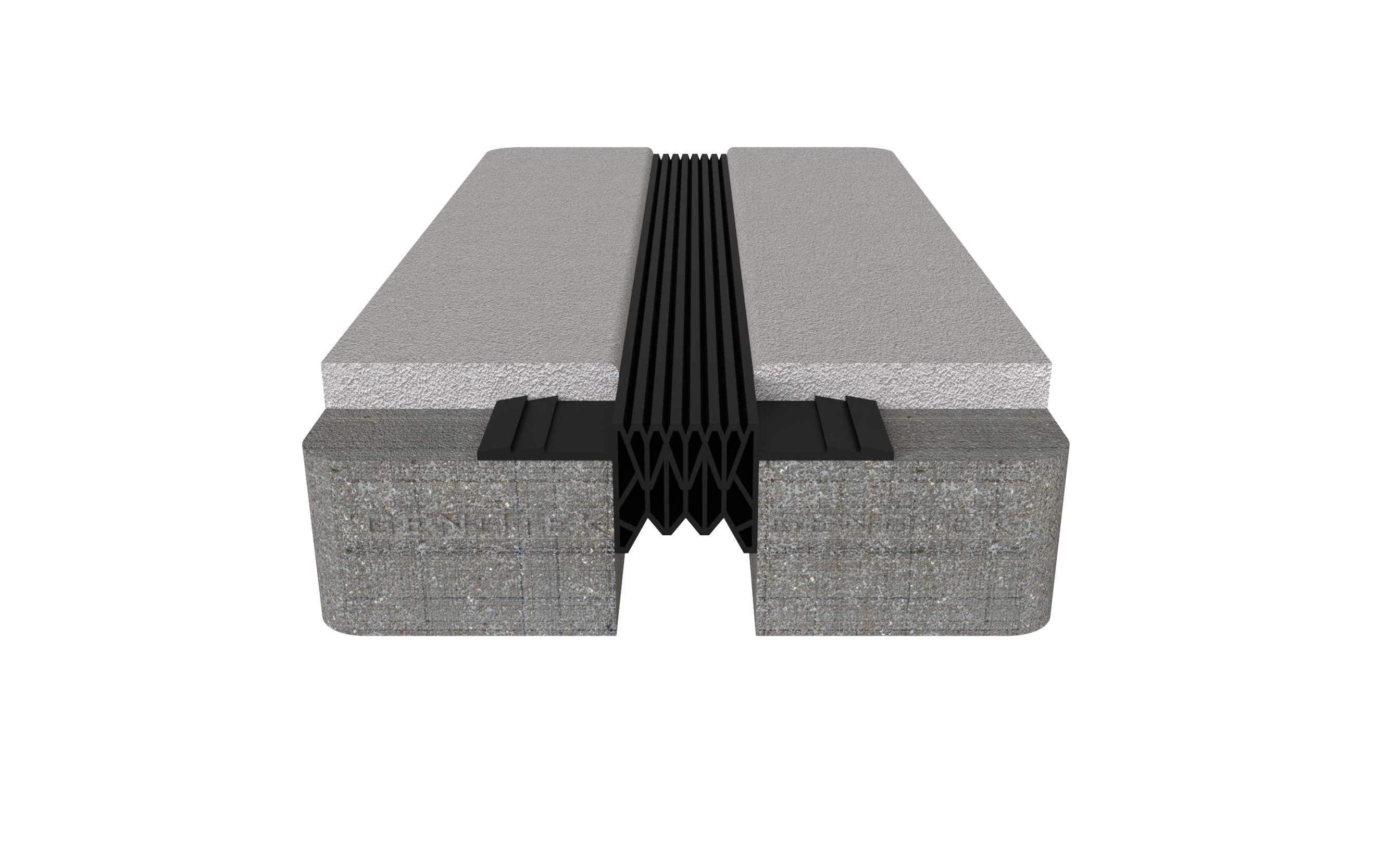

An expansion joint is a structural gap designed to accommodate the movement of a building in a controlled manner, preventing damage to the internal and external finishes of a building.

Expansion joints run throughout a building, in walls, ceilings, and floors.

What is the use of the Expansion Joint Cover System?

The expansion joint cover provides a closed transition (cover) for pedestrians, vehicles, etc. through the expansion opening and is unaffected by the relative motion of the two surfaces on either side of the joint.

In other words, an expansion joint cover is a cover that protects the space or gap between two or more building materials.

An expansion joint is required in a building design to accommodate any building movement, so it is critical that the cover does not restrict movement, but an expansion joint must be covered for safety reasons.

Architects need to consider multiple aspects while designing the structure of the building, they often overlook expansion joints.

This can lead to serious concerns in life span of the structure due to thermal and seismic(earthquake) related stress.

This image depicts what happened to a structure in Turkey during an earthquake in 1999 due to lack of an expansion joint.

In less extreme circumstances, a building's structural elements, such as walls, floors, and ceilings, may develop cracks as a result of improper planning for a joint opening.

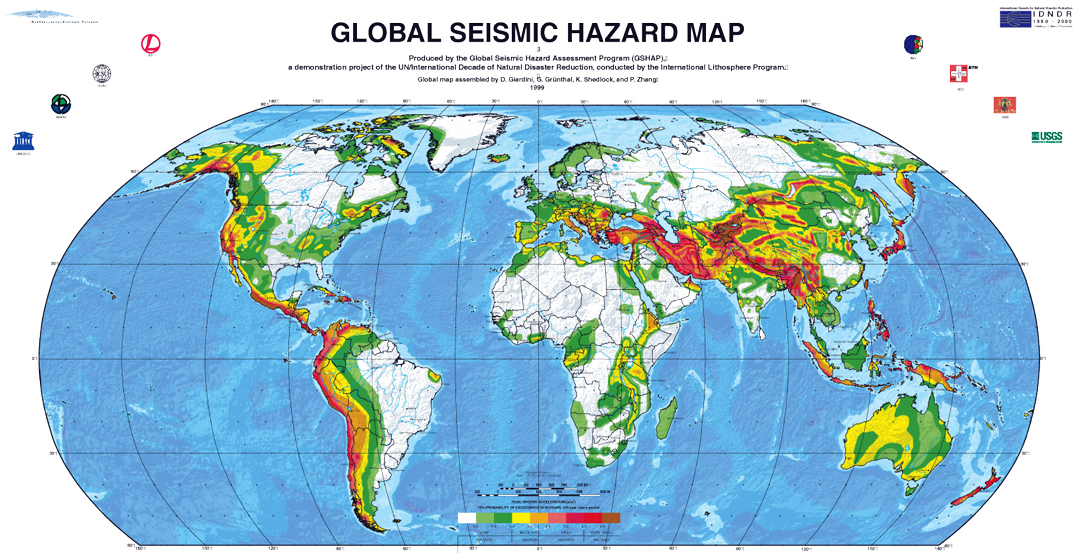

Depending on the geographical location of a building, expansion joint openings can be as small as 25 mm wide or as large as several feet wide.

The probability of an earthquake occurring in various areas is depicted on this World map. Yellow, orange, red, pink, and brown areas will almost certainly require large seismic expansion joint openings, whereas green, light green, and white areas will almost certainly require smaller joint openings to accommodate thermal movement.

Building settling and movement can occur everywhere, and wind sway is taken into account when predicting where hurricanes will strike.

Movement Basics

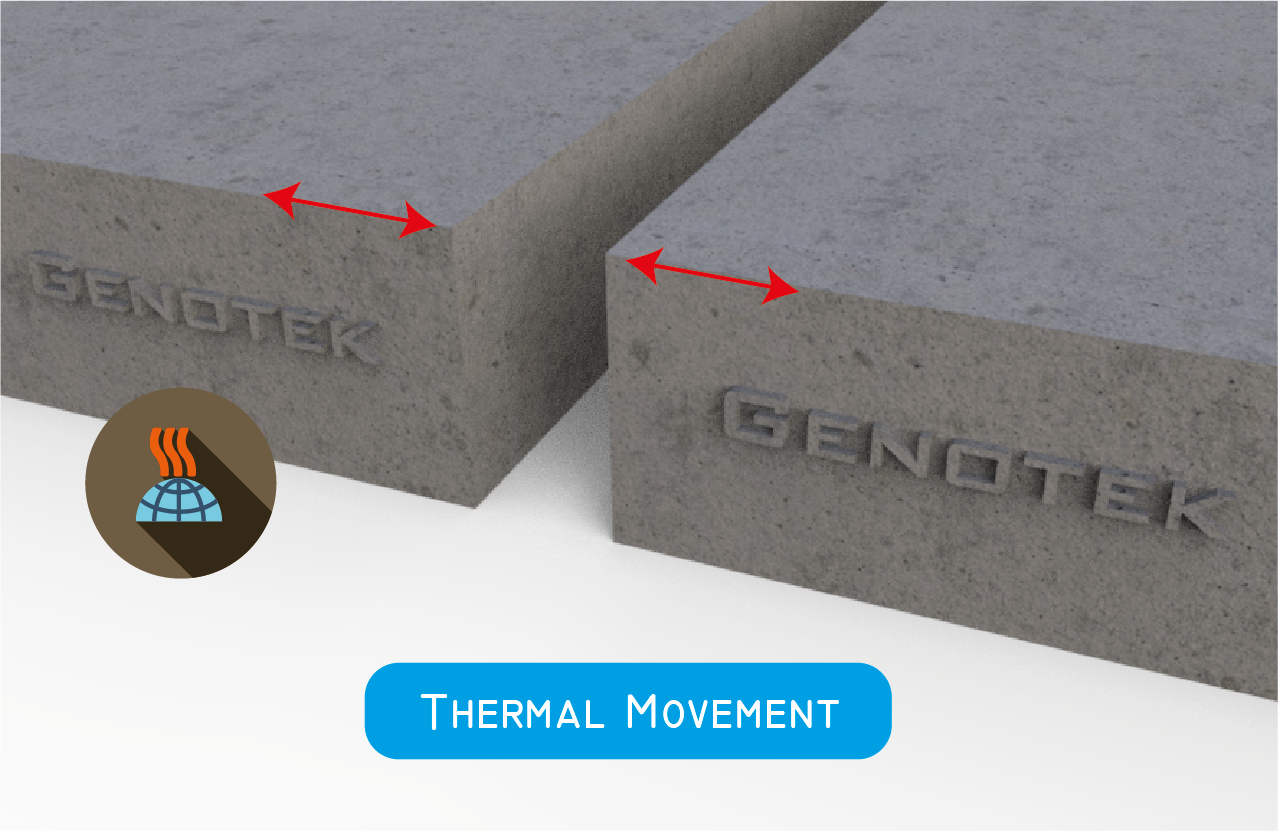

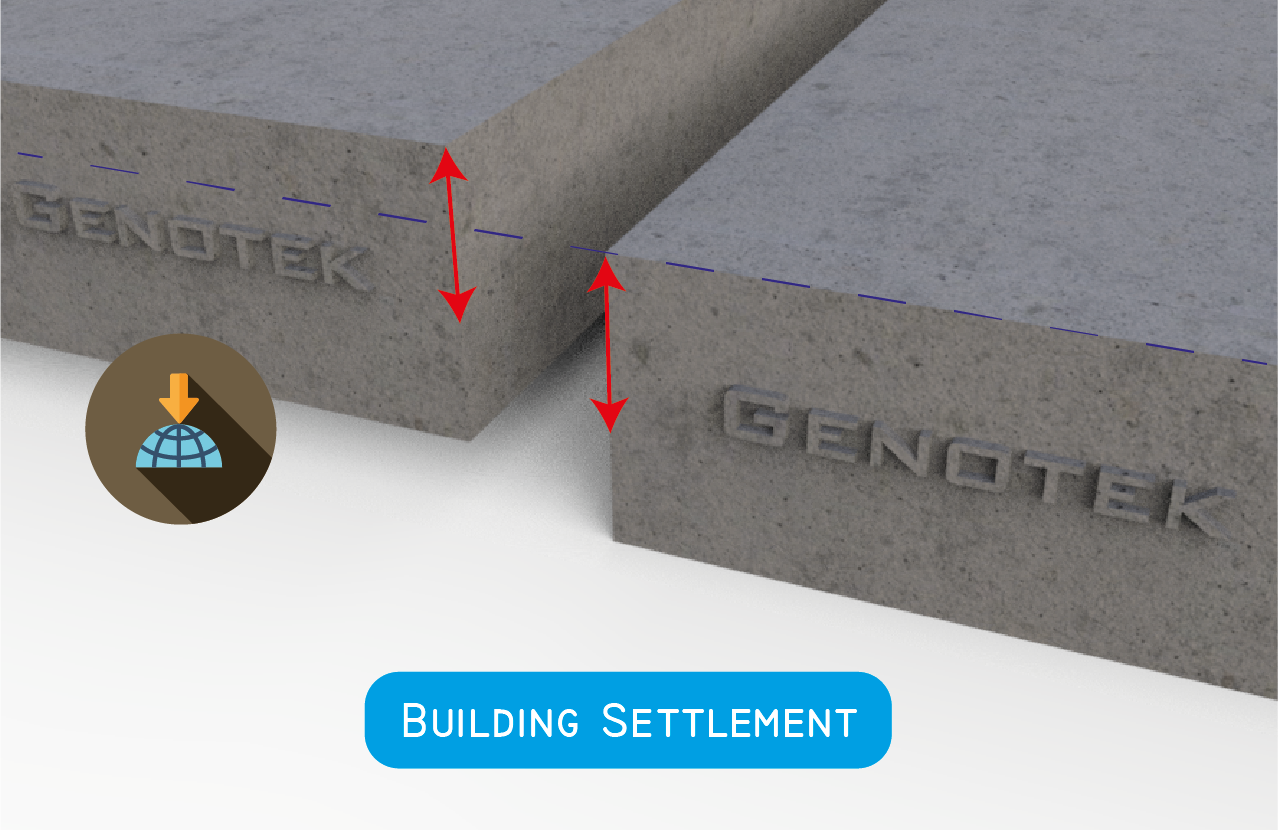

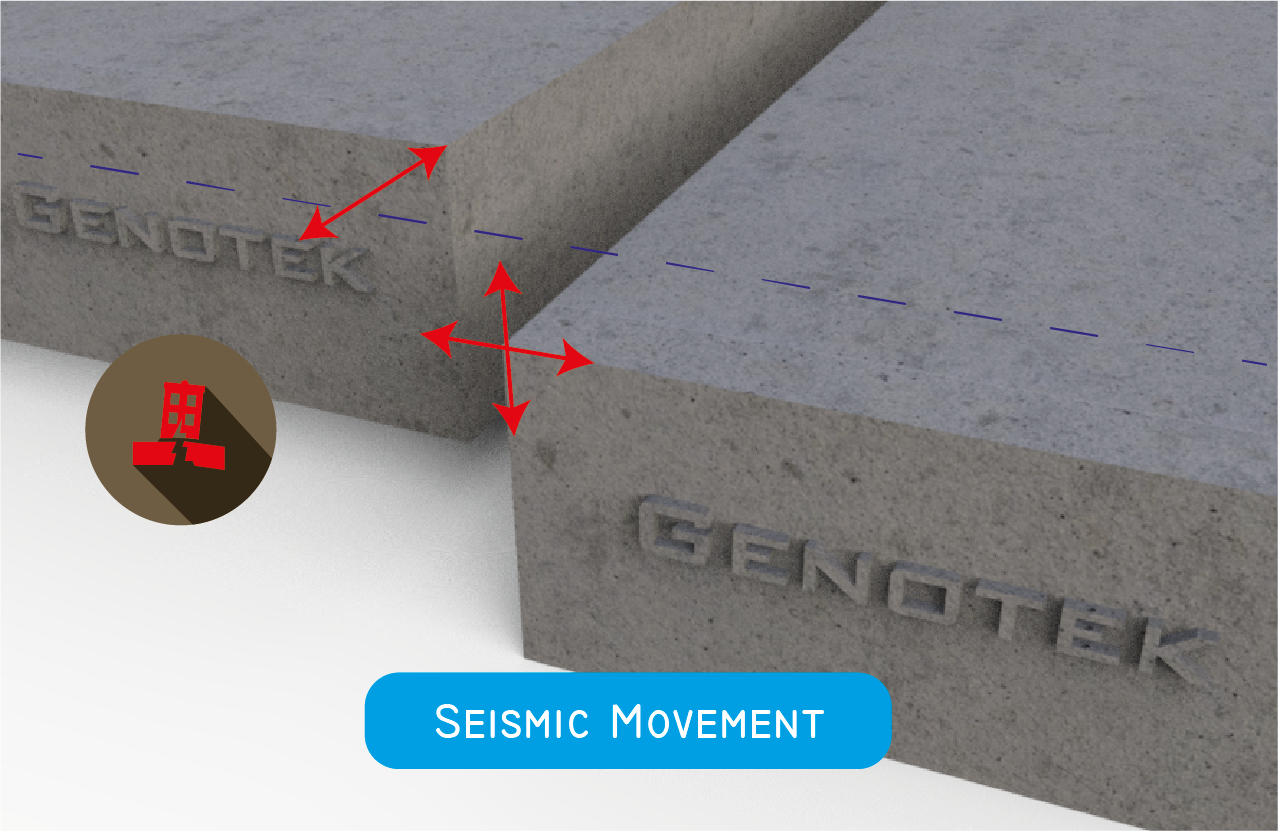

Next, we’ll take a look at how an expansion joint cover will function based on the type of movement that is expected. There are four types of movement: thermal expansion or contraction, building settlement, wind sway, and seismic activity.

Thermal movement is the most common and occurs when a building expands or contracts due to external temperatures that cause the building to heat up or cool down. For example, in some parts of the country, you can have large temperature swings between morning and evening, so the materials in a building cause the building to shrink or contract in cooler weather but expand throughout the day as it gets warmer.

Another common type of movement is building settlement. It is caused by the dead and live loads of the structure on the supporting foundations and typically occurs when a new structure is connected to an existing structure. Over time, the new building will “settle” but will do so at a different rate than that of the existing building.

The third type of movement, wind sway, occurs in tall buildings, which are subject to a swaying movement when the wind blows. In windy cities like Chicago, or in areas that are subject to hurricanes, wind sway needs to be taken into consideration. In instances when there is a lower portion of a building next to a taller portion of a building, as seen in the right photo, an expansion joint would be found between the lower portion and the taller portion of the building. This is because the taller portion of the building is more subject to powerful gusts of wind.

Seismic movement is infrequent, but it can do a lot of damage depending on the severity of the “wave” motion in the ground when the seismic event occurs. Seismic movement can occur in any combination of directions. It is sporadic and typically short-lived, versus thermal movement that could cause the building to move just a little bit every day for a prolonged period of time.

Understanding the Gap and Movement Capacity

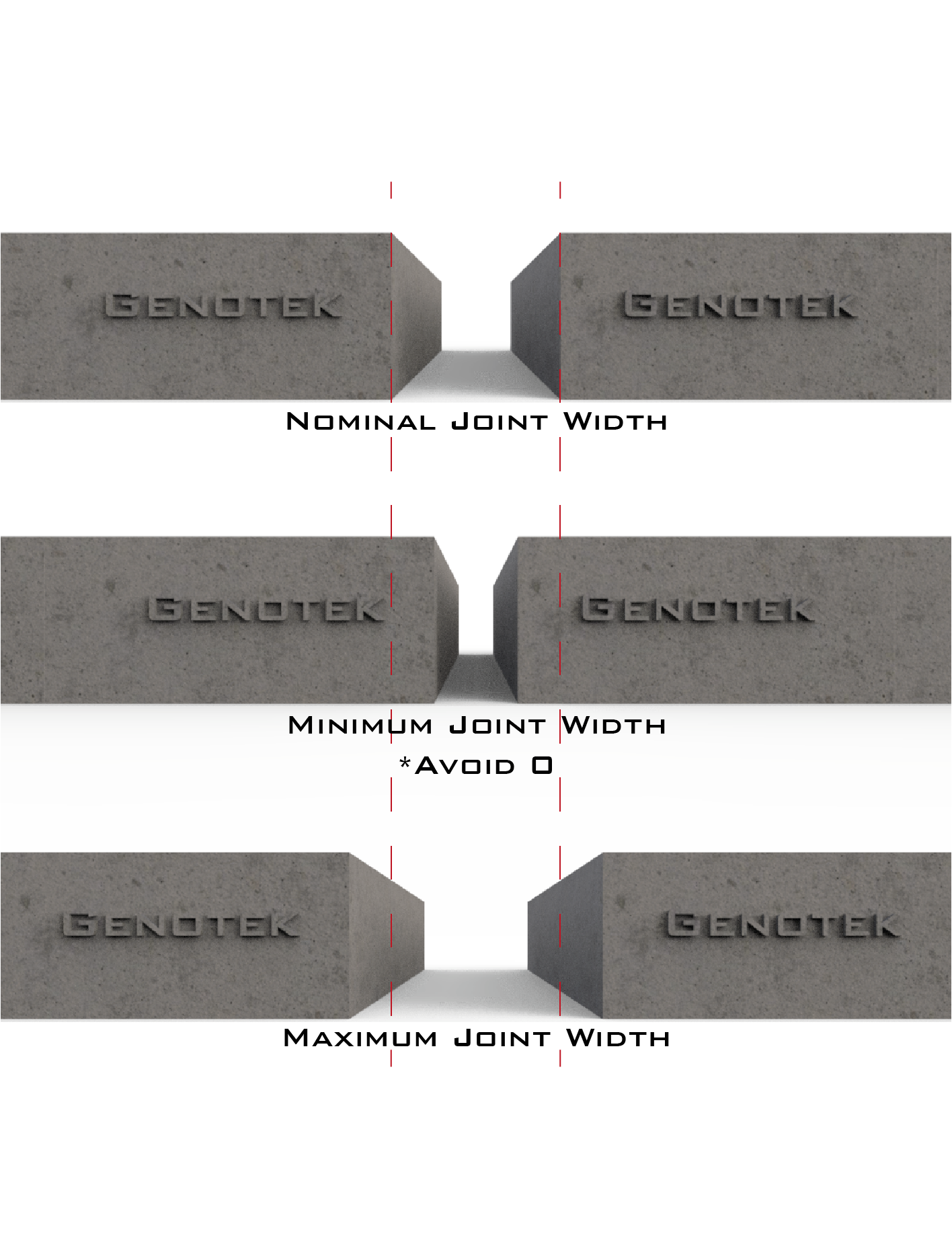

In this example, we’ll say the engineer gave a nominal joint width of 50mm that closes 25mm and opens 25mm.

The nominal joint width of an expansion joint cover is the specified size of the joint opening or the width of the joint without movement. The nominal joint width in this example is 50mm.

The minimum joint width is defined as the narrowest linear gap that the joint system tolerates or is expected to close to. For instance, if a 50mm nominal joint is expected to close 25mm, then the minimum joint width would be 25mm (e.g., 50mm (nominal) – 25mm (close) = 25mm minimum joint width). It is important to note that the minimum joint width should never be zero (0mm). This is because there may be building materials, such as a fire barrier or turnbars, that may need to be installed inside the joint opening, in which case closing the joint to 0mm would not be possible. This issue will be addressed later on in the presentation.

The maximum joint width is defined as the widest linear gap that a joint system is expected to tolerate and in which it can perform its designed function without damaging its functional capabilities (e.g., 50mm (nominal) + 25mm (open) = 75mm maximum joint width).

Where are Expansion Joint Covers Required?

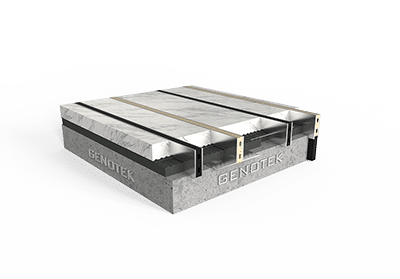

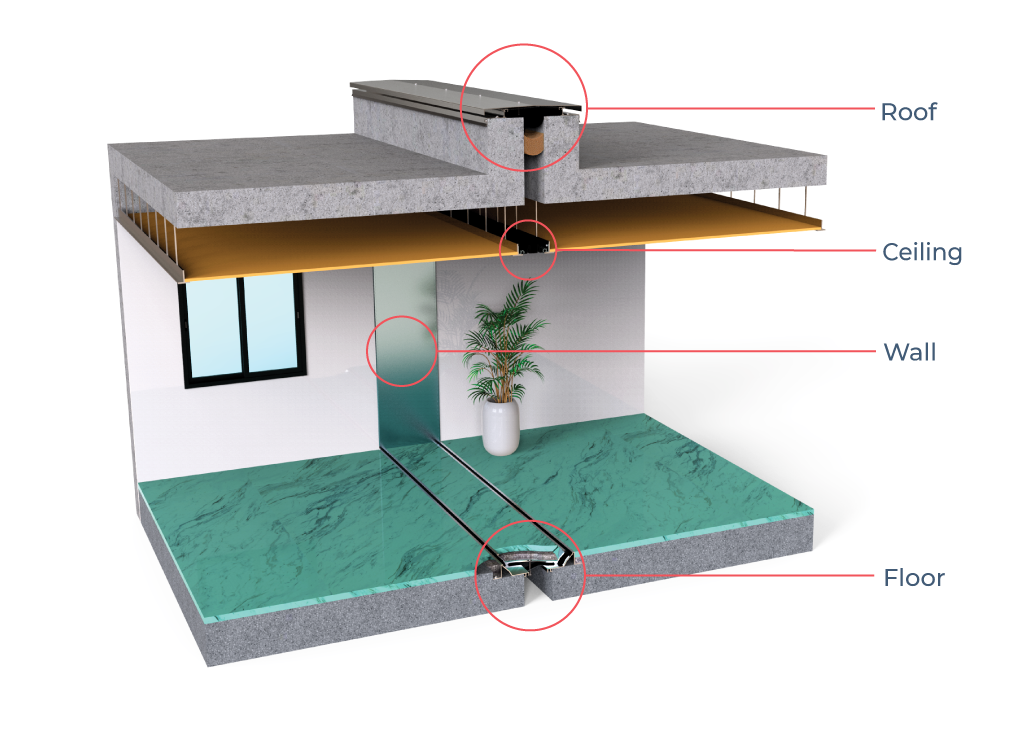

This image shows a typical location of a space or gap that must be left in a building to allow for potential, thermal, wind sway, settlement, and/or seismic movement.

An expansion joint completely cuts the building through all of its elements. They usually run from top to bottom and front to back, and they get wider as you get higher up in the building.

When a building moves, expansion joints provide some flexibility. As seen in this section cut, this affects the interior floors, walls, and ceiling, as well as the exterior walls and roof of the building. When an expansion joint enters a building, it must continue through the building. If it does not, the building's components will be unable to move independently.

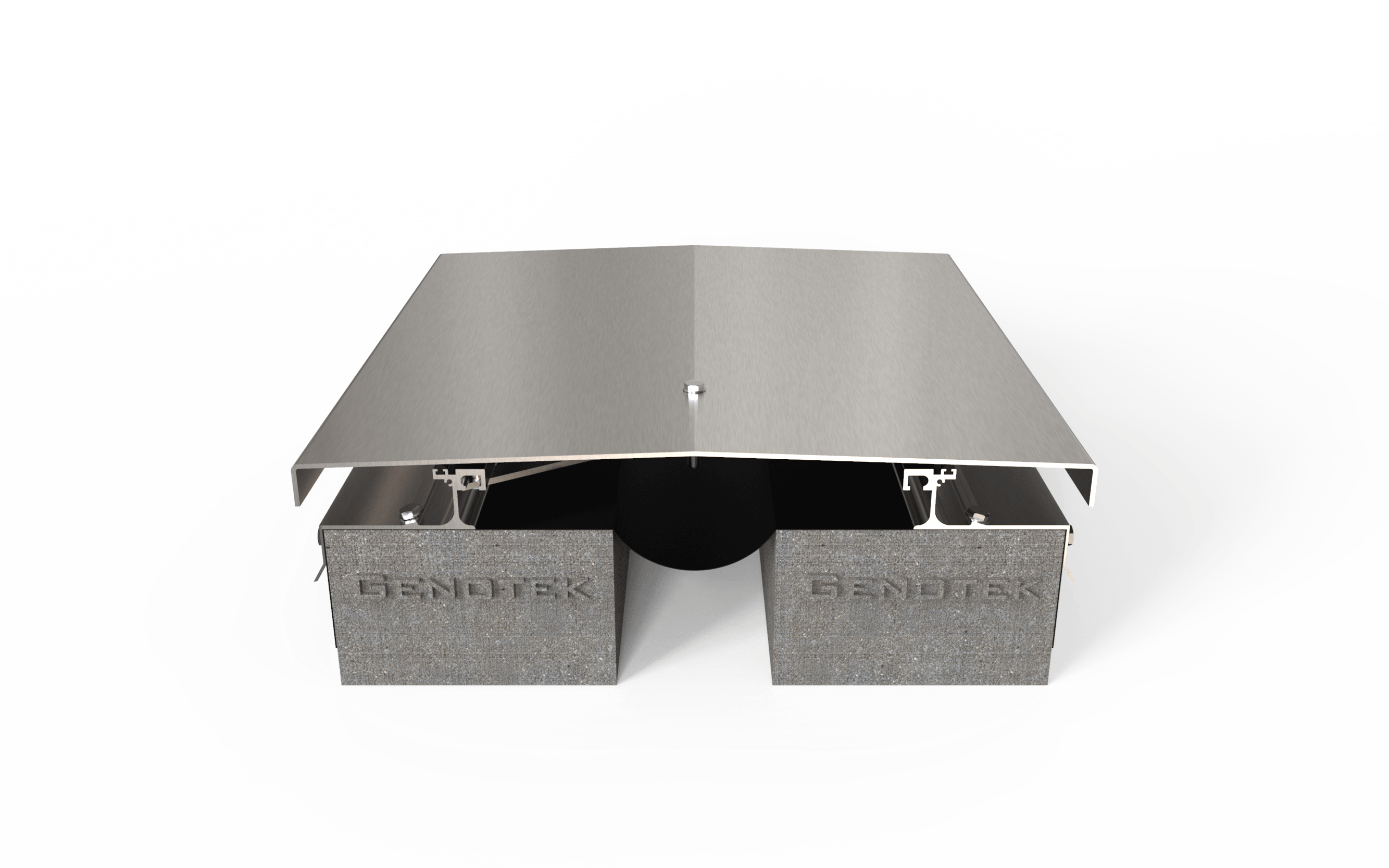

How to choose the correct expansion joint?

- Based on Movement Capacity

- Thermal

- Seismic

- Based on Location

- Interior

- Exterior

- Exterior (Open-Air)

- Based on Application

- Front of House

- Back of House

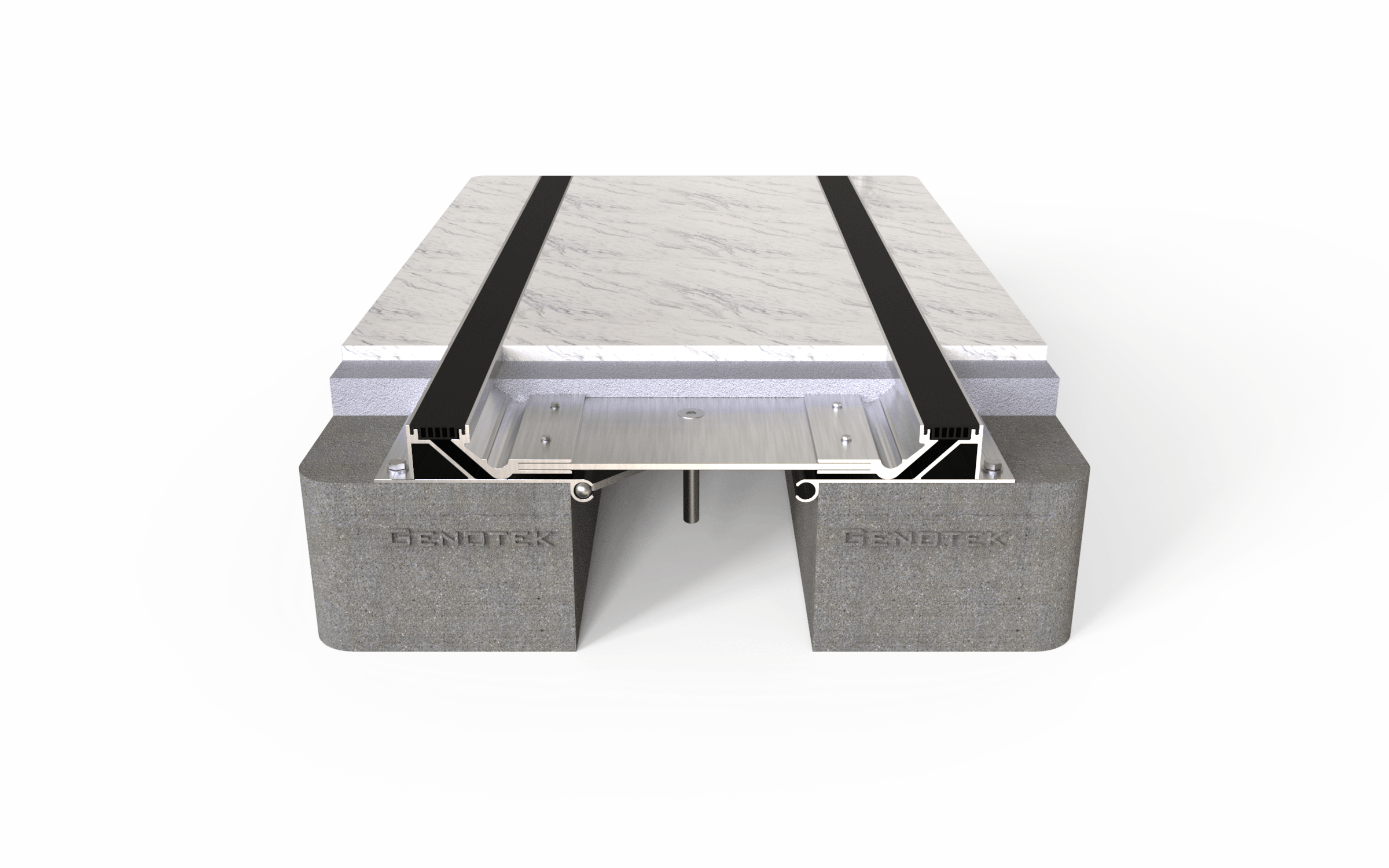

- Based on Load Capacity

- Pedestrian

- Light Vehicular

- Heavy Vehicular

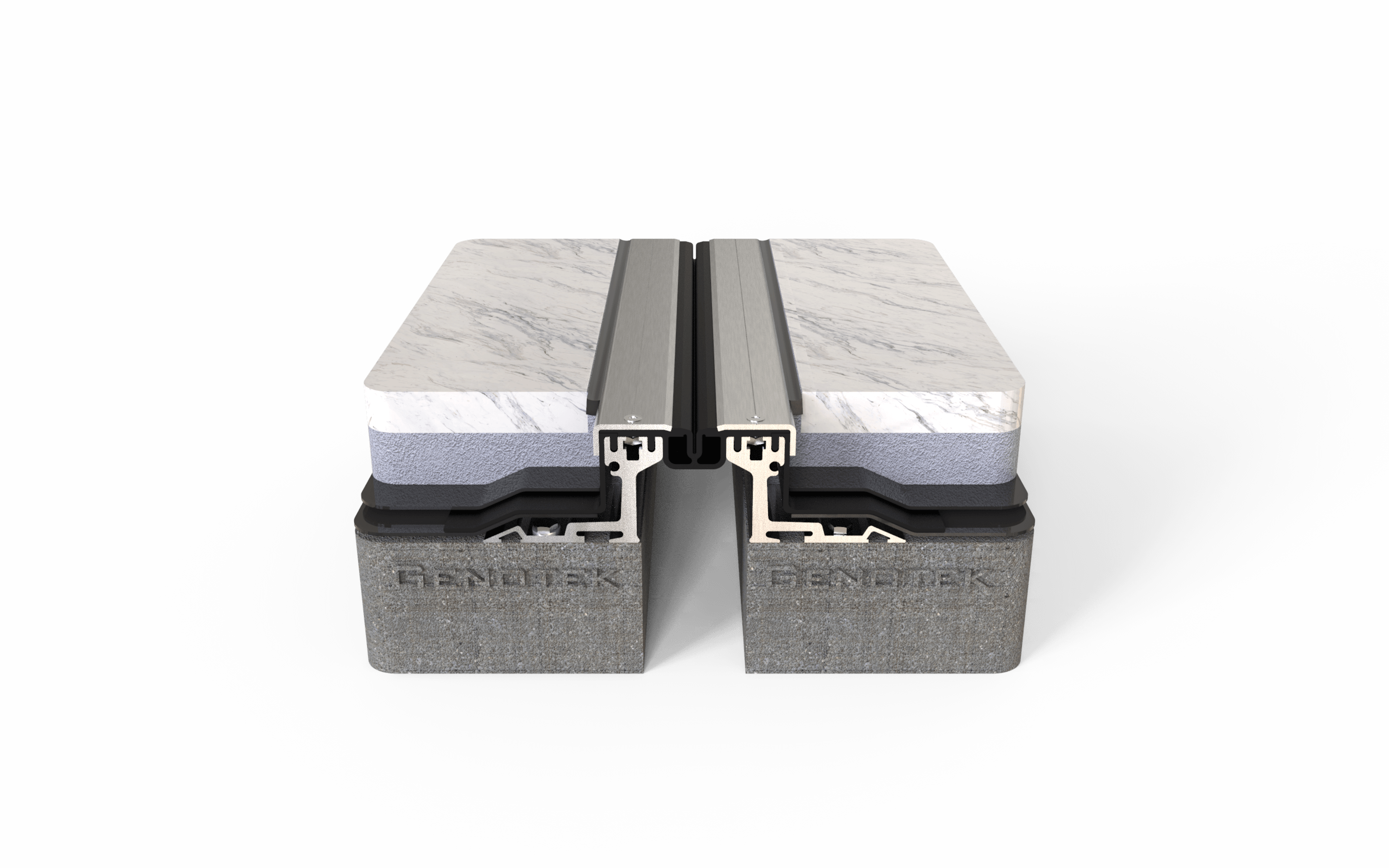

- Based on Component Material

- All-Aluminum

- Rubber

- Aluminum + Rubber

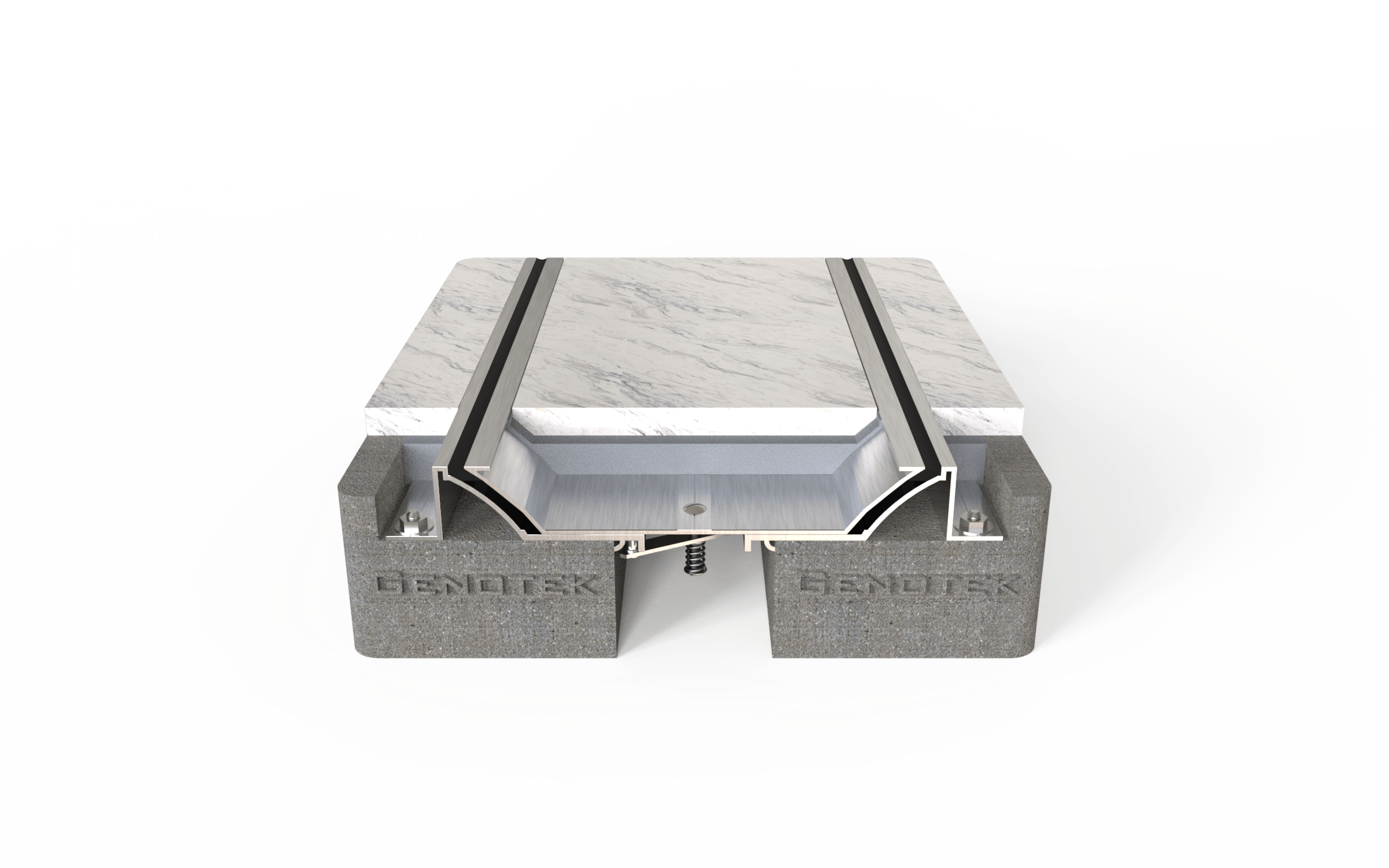

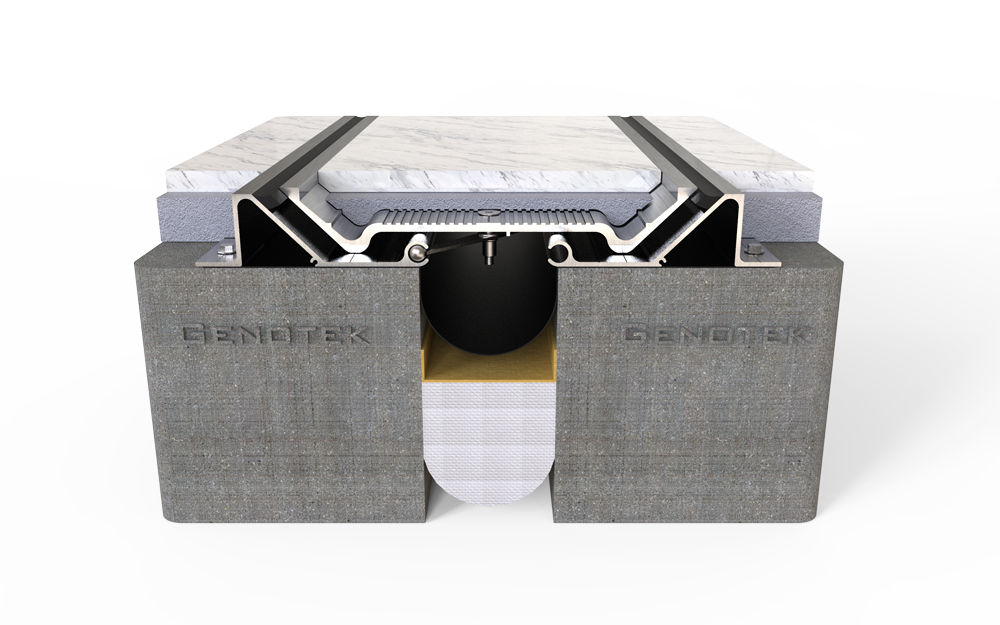

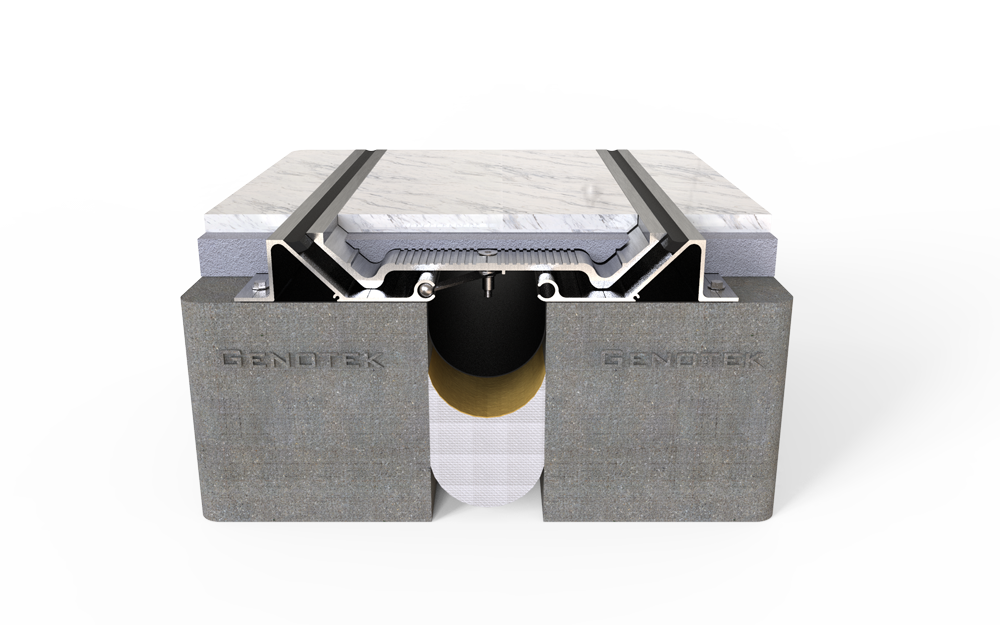

- Based on Waterproofing Requirements

Different types of Waterproofing (Water-tight) options.

Full System of Expansion Joint Cover with Different Types of Fire Barrier System

Water Barrier and Rockwool and Sealant Fire Barrier System

Water Barrier With Mattress Type Fire Barrier System

Water Barrier With Blanket Type Fire Barrier System

Water Barrier With Rope Type Fire Barrier System

What type of projects to are expansion joints most often found in?

Expansion Joint Covers are most often used in large quantities in large horizontal (wide) structures such as:

- Hospitals

- Shopping Malls

- Airports

- Education Campus

- Luxury Hotel Resorts

- Multi-Story Car Park

- Government Buildings

- Stadiums

- Commercial and Residential Complex Podiums

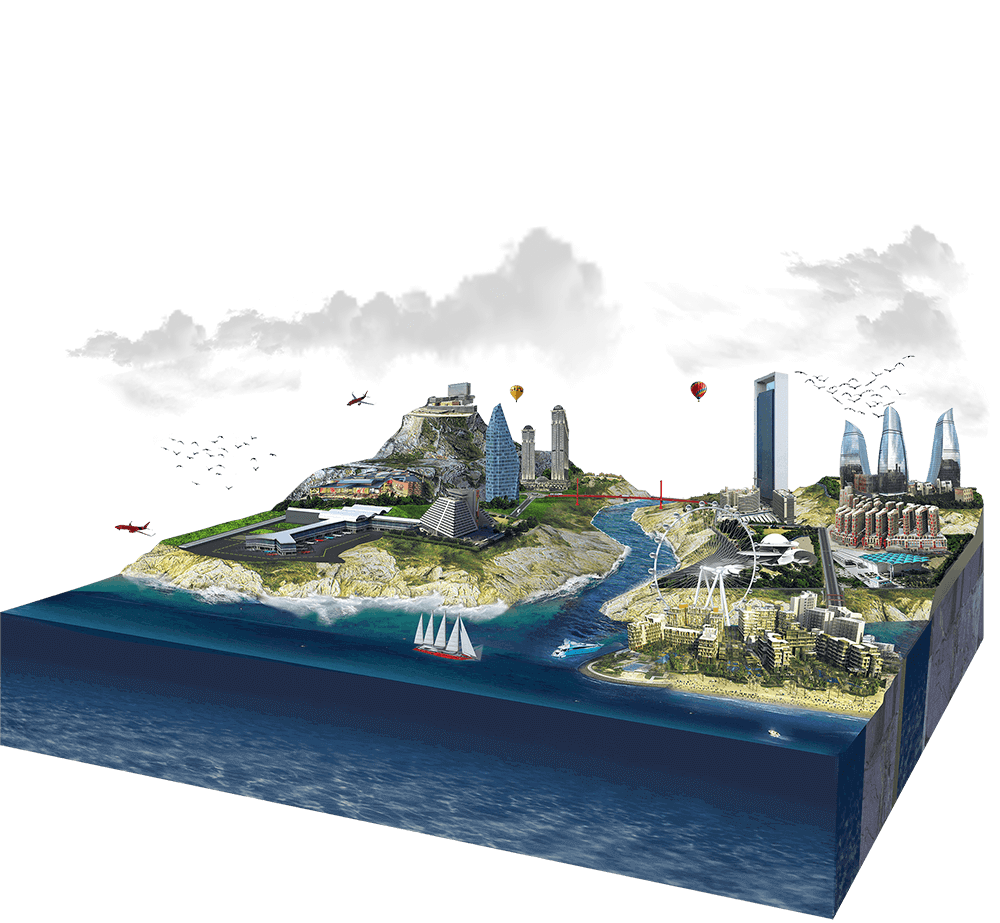

Here are some of our key reference projects;

- Caesar's Palace Hotel, Bluewater Island, Dubai, United Arab Emirates

- Cleveland Clinic Hospital, Abu Dhabi, United Arab Emirates

- New Doha International Airport, Doha, Qatar

- Kuwait International Airport, Farwaniya, Kuwait

- Jabal Omar Development Project, Kingdom of Saudi Arabia

- Flame Towers, Baku, Azerbaijan

- Al Wakrah Stadium, Al Wakrah, Qatar

- Qatar National Museum, Doha , Qatar

- Louvre Museum, Abu Dhabi, United Arab Emirates

- Mumbai Airport Expansion, Mumbai, India

Partners

.png?width=283&height=125&name=5ed0feabc534bd16344035d8_ambb-interiors%20(1).png)

Our Commitment to the environment

Genotek™ embraces and enables sustainability in its operations, culture, and through the performance of its products. Genotek™ supports green building practices and energy-efficient design in all new and remedial construction.

The unique features of Genotek™ products are synchronous with LEED design principles and, as has been demonstrated in numerous projects can contribute to achieving LEED certification.

Our Corporate Social Responsibility

Our core values drive us to be a responsible member of the communities where we operate, and that includes partnering with nonprofit organizations to strengthen the places we call home. We thoughtfully realigned our social responsibility program to better reflect our core values and support our business purpose. We engage in our communities in a number of ways:

Corporate Giving

We partner with local nonprofit organizations to meet community needs through financial and in-kind donations. We do this by supporting organizations in four giving categories. Request a donation.

Charitable Donations

Supporting organizations that align with our core values and business strategies.

Volunteering

We partner with local nonprofit organizations to meet community needs through financial and in-kind donations. We do this by supporting organizations in four giving categories. Request a donation.

Mentoring

Ikan has built one of the largest mentoring programs in the state. Each week during the school year, more than 25 employees visit one on one with elementary, middle and high school students during their workday.